|

|

| |

|

| VIP-Energy MANUAL VERSION 5 ENGLISH |

|

| |

|

|

|

| |

|

|

|

TABLE OF CONTENTS

Introduction

Generic

Validation

Application manual

Data files in VIP-Energy

Calculation guide

Graphical interface design

Generic information

Main window

Input windows

Time schedules

Files

Catalog data

1-dimensional Building part

Windows, doors

Fresh air vents

2-dimensional building part

3-dimensional building part

Control of Solar protection, air permability, U-factor

Material catalog

Compound material

Form factors for wind pressure

Generic

Standard value

Calculation of wind pressure

Using catalog data

Operation cases

Energy price

Heat pumps

Type of heat sources

Refrigerant

Highest / Lowest temperature

Loss coefficient

Heat gas exchanger

Distribution

Test results and test standards

Solar collectors

Generic

Absorption coefficient

Loss coefficient 1

Loss coefficient 2

Accumulator volume

Temperatures

Circulation pump power

Accumulator simulation model

Solar cells

Generic

Efficiency

Temperature coefficient

Intensity coefficient

Highest and lowest cell temperature

Heat absorption coefficient

Heat capacity

Heat loss coefficient

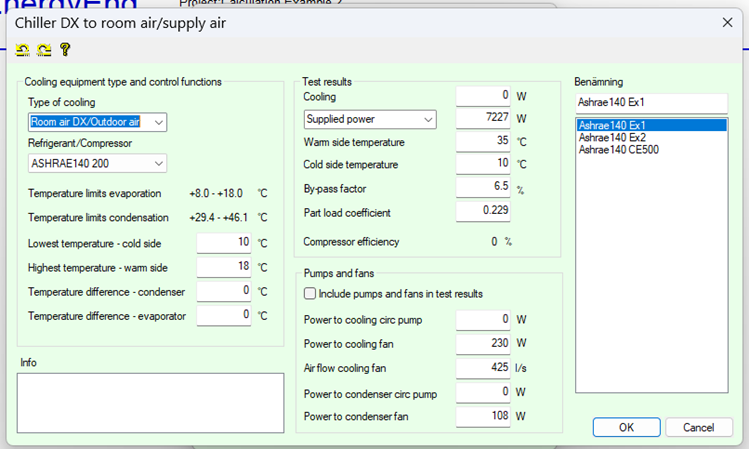

Cooling machine DX-Cooling (Only available in validation mode)

Generic

Type of cooling system

Refrigerant / Compressor performance

Highest Lowest temperature

Temperature differences at condenser and evaporator

Test results

Cooling capacity

COP cooling / Supplied power

Temperatures

By-pass factor

Part load coefficient

Compressor efficiency

Air flow cooling fan

Power to condenser fan and pump

Upgrade catalog data

Import catalog data

Download Catalog data

Report Generator

Project data

Title

Climate information

City

Air pressure outside

Horizontal angle

Locked wind direction

Wind velocity % of climate file

Solar reflection from ground surface

Designing outdoor temperature

Load climate data

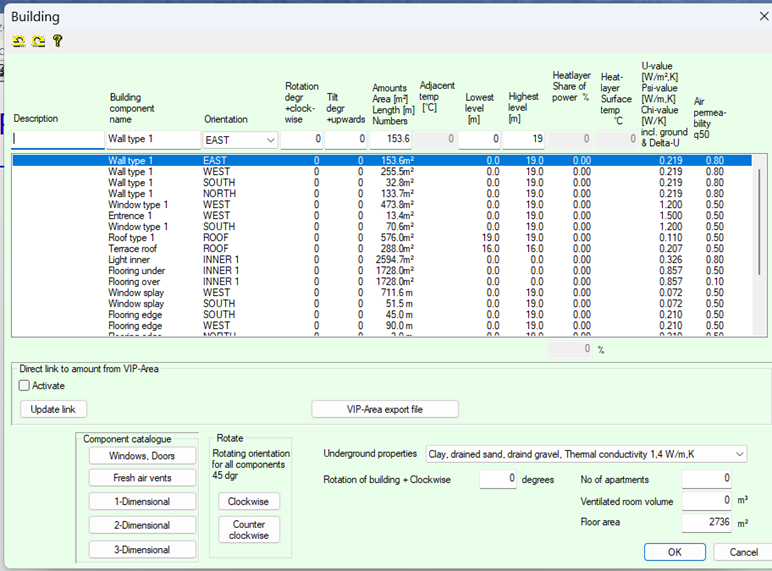

Building

Generic

Orientation

Rotation and tilting

Heat layers and share of heating demand

Ventilation volume

Floor area

Number of apartments

The angle towards south

Levels

Data import from VIP-Area

Time schedule for operation

Generic

Time schedules

Date function

Remaining time

Operation case

Operation hours

Operation year

Copy

Limitations

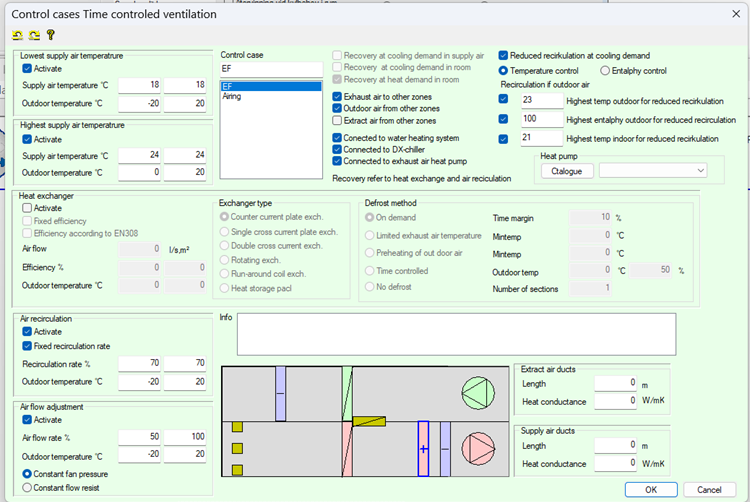

Time scheduled ventilation systems

Generic

Fan pressure

Fan efficiency

Operation hours

Operation year

Control case catalog

Generic

Lowest supply air temperature

Highest allowed supply air temperature

Energy efficiency exchanger

Efficiency recirculation

Regulation of flow from outdoor temperature

Cool recovery

Air supply from other zones

Connected to water heating system

Connected to DX-cooling machine (Only in validation function mode)

Connected to exhaust air heat pump

Fixed efficiency or heat exchange

Fixed efficiency for recirculation

Reduced recirculation at cooling demand(Only in validation function mode)

Highest temperature outdoor for reduced recirculation(Only in validation function mode)

Highest room temperature for reduced recirculation(Only in validation function mode)

Temperature controlled ventilation

Temperature controlled ventilation with passive forced flow

Forcing air flow over room temperature

Lowest difference temperature room-supply air

Total forcing flow supply air

Total forcing flow extract air

Fan pressure supply air

Efficiency supply air fan

Fan pressure extract air

Efficiency extract air fan

Temperature controlled ventilation with cooling (VAV system)

4.7.7.2.1. Lowest supply air temperature

4.7.7.2.2. Exchange efficiency

4.7.7.2.3. Controlling sequence

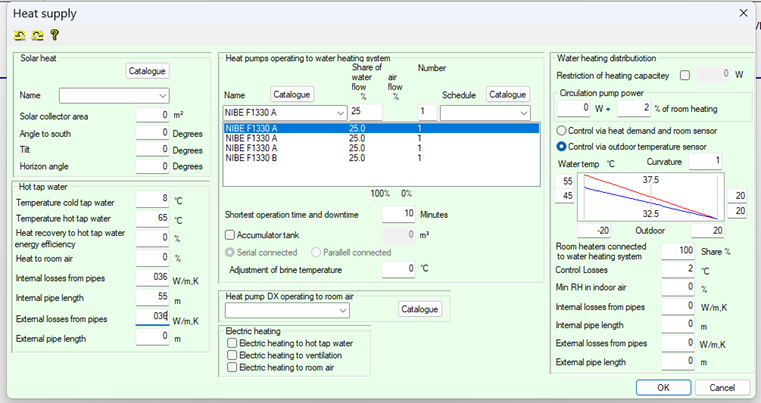

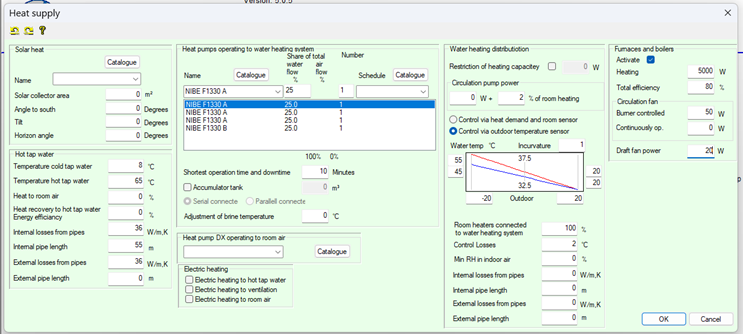

Heat supply

Generic

Solar Heating

Solar collector area

Angle to south

Inclination

Horizon angle

Heat supply

Restriction of heating capacity

Electric power circulation pumps

Water temperatures in heating system

Heat demand covered by water heating

Heat pump

Furnaces and boilers(Only validation mode)

Hot tap water

Consumption

Heat recovery

Temperatures

Energy efficiency

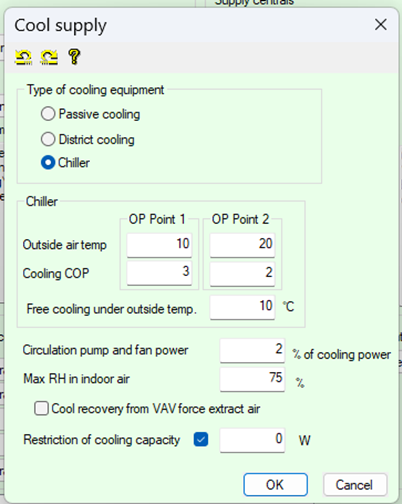

Cool supply

Generic

Passive cooling

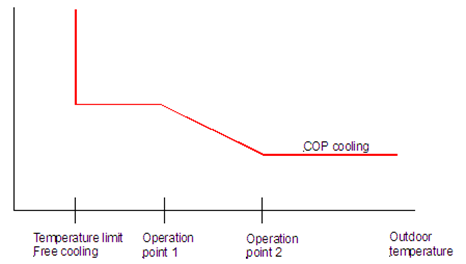

Cooling machine water cooling system

COP cooling

Limit for free cooling

Cooling machine DX-cooling(Only validation mode)

District cooling

Power to circulation pumps

Maximum RH in room air

Cooling recovery for VAV forced exhaust air

Restriction of cooling capacity

Economy

Generic

Time schedules

Remaining time

Energy prices

Hours and weeks

Date function

Copy function

Restrictions:

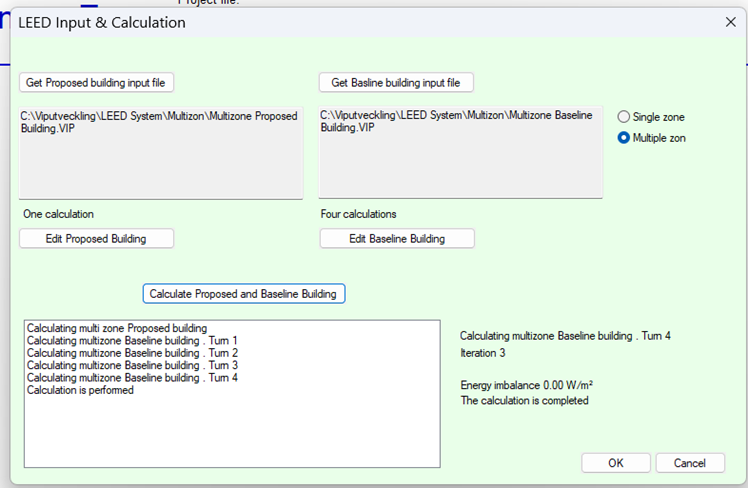

Demands according to Ashrae 90.1 and LEED

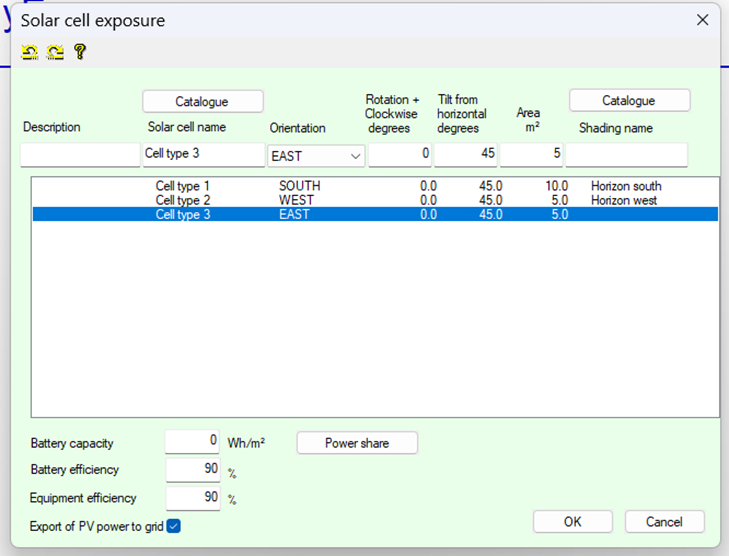

Exposure an orientation of solar cells

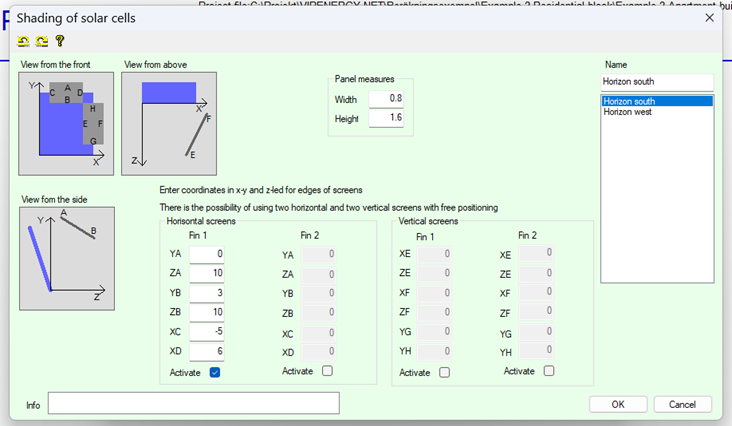

Shading of solar cells

Calculate

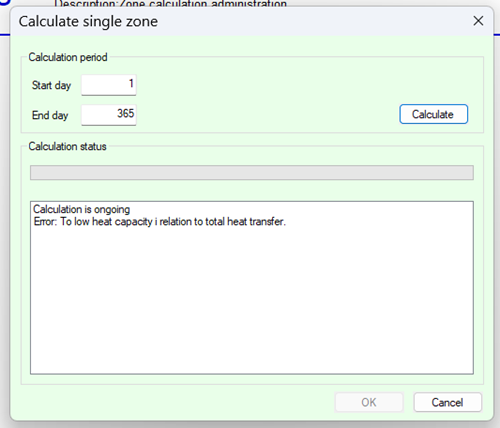

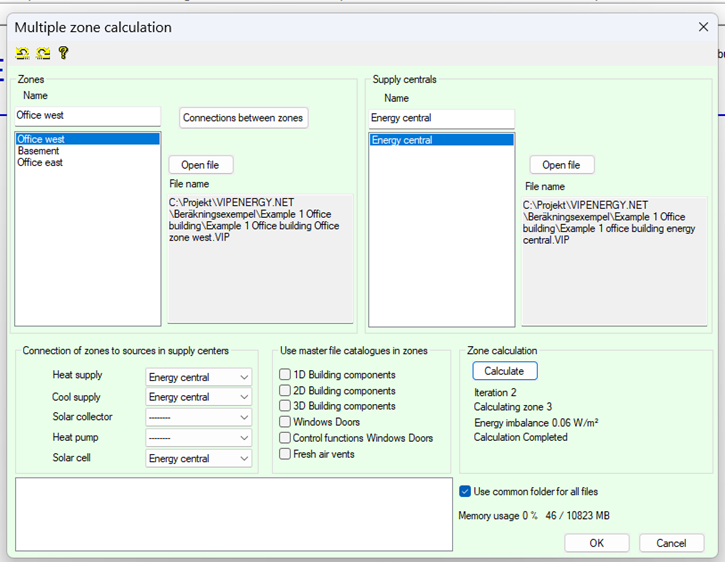

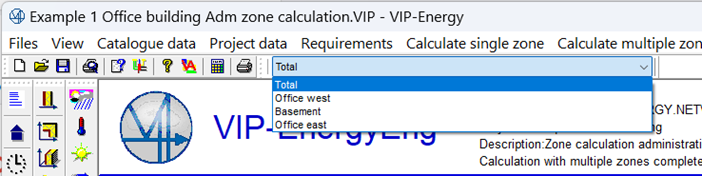

Zone calculation

Generic

Initiation of supply centrals

Initiation of zones

Connecting supply centrals to zones

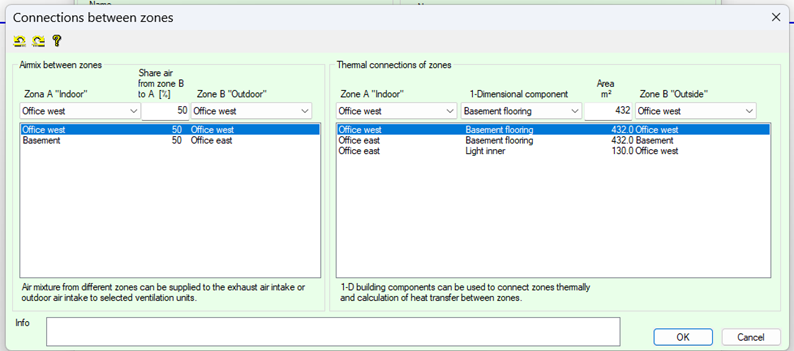

Connecting zones

Air temperature an moister transmission between zones

Common directory

Use catalog data from master file in all zones

Calculation

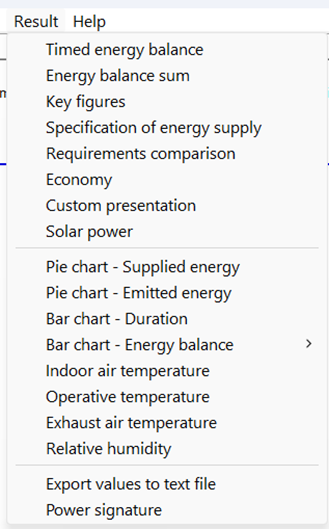

Results

Generic

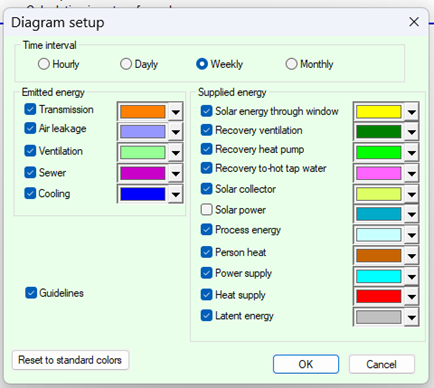

Energy map

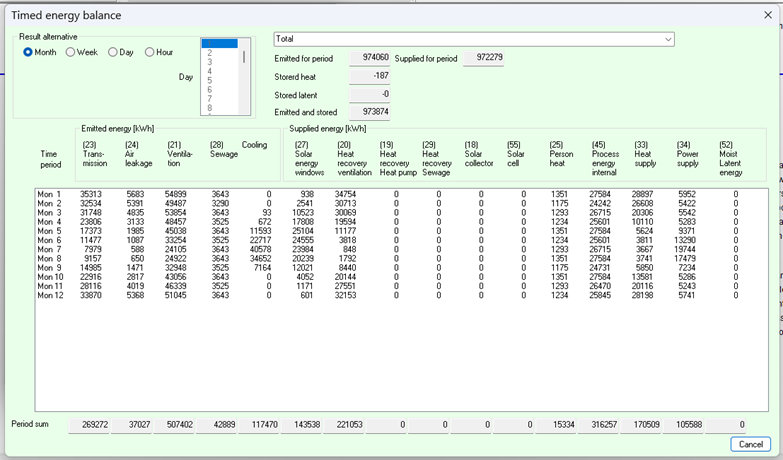

Result in time steps

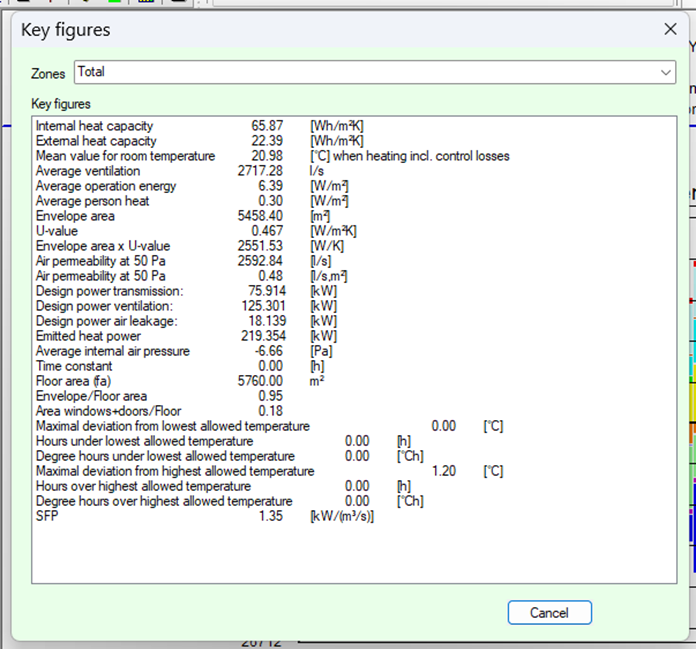

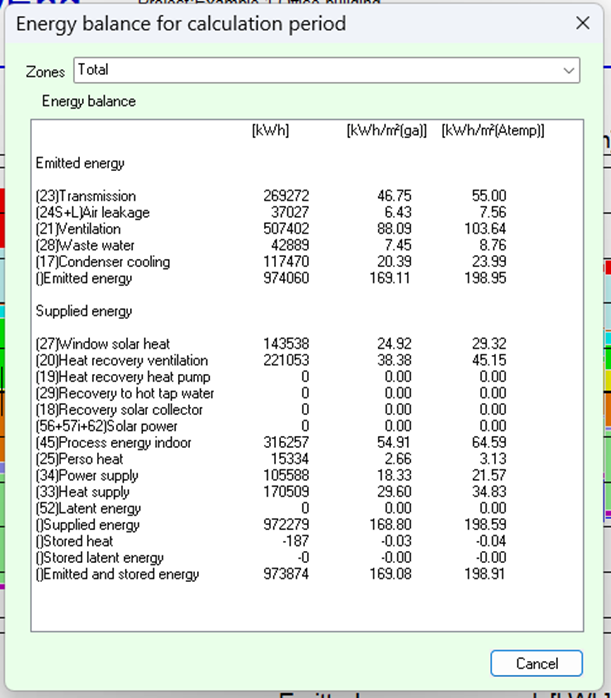

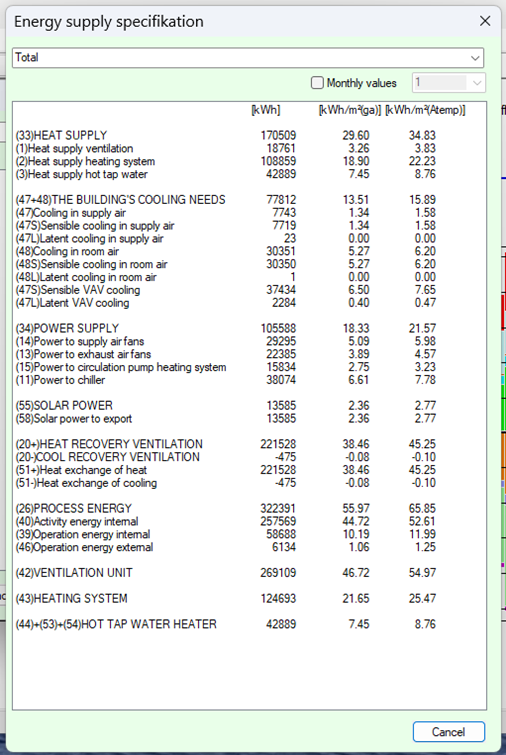

Key Values and energy balance

Specification of energy flows

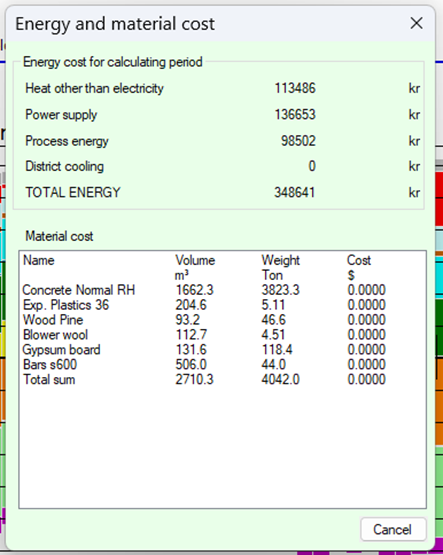

Economy

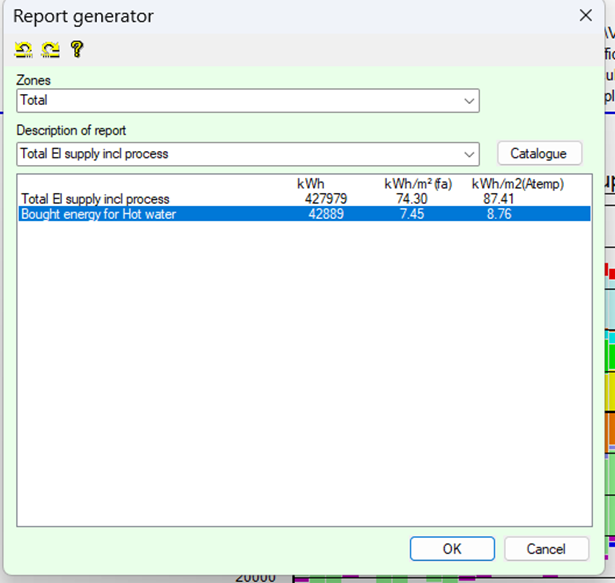

Report generator

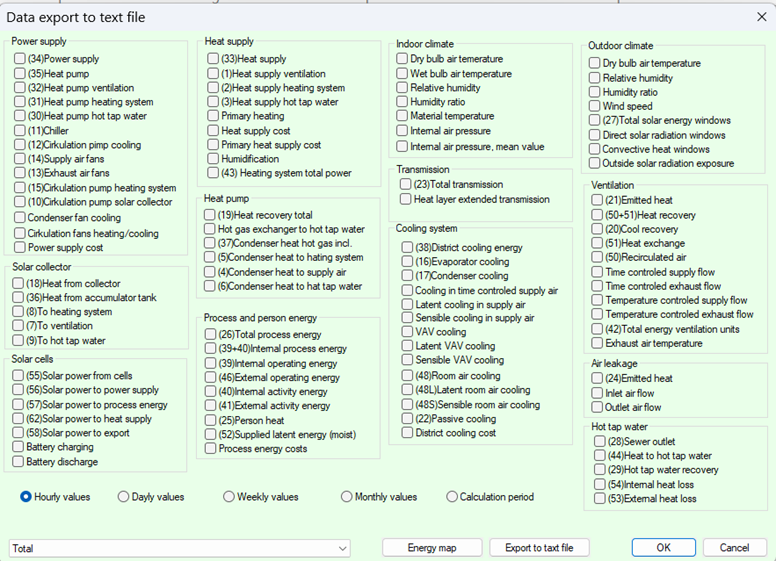

Value export to text file

Graphical record

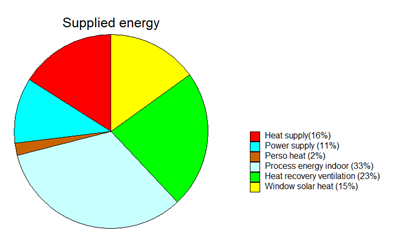

Pie chart supplied energy

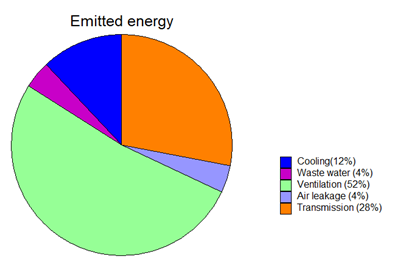

Pie chart emitted energy

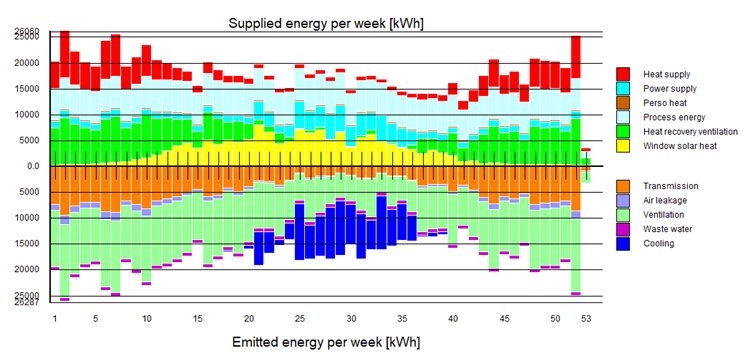

Bar chart energy balance

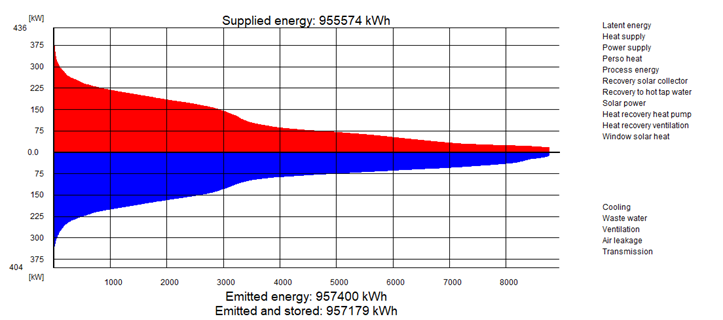

Bar chart duration diagram

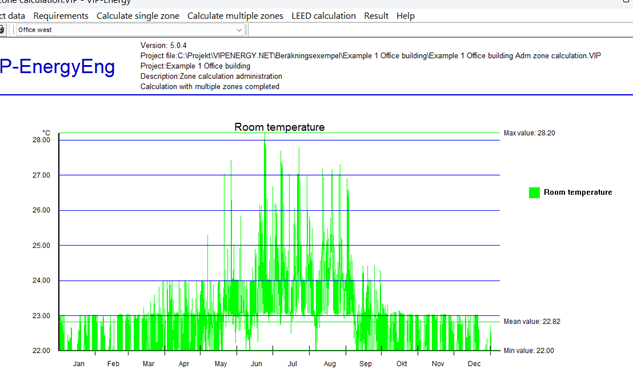

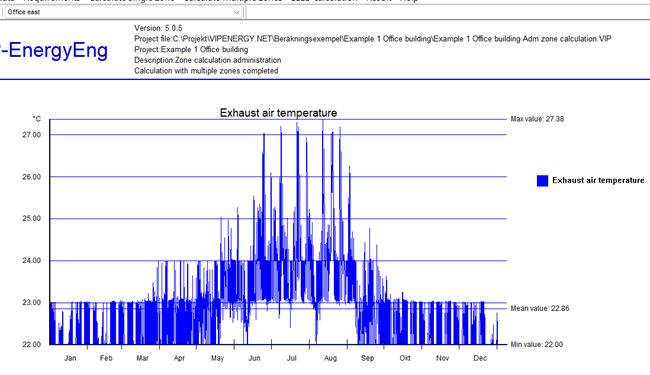

Room temperatures

Multi zone calculation

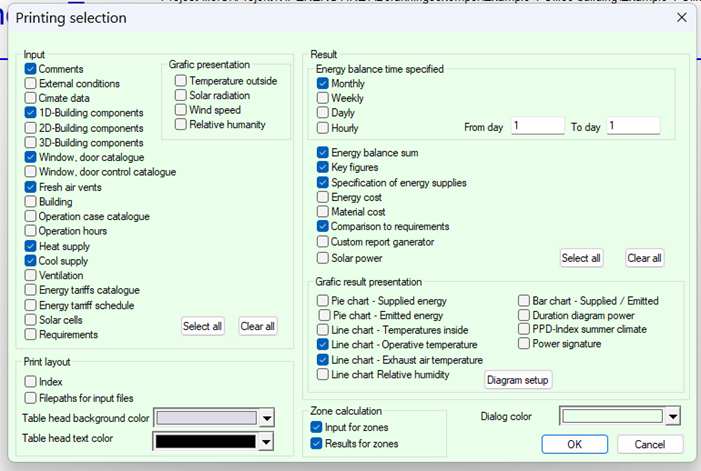

Printing

Printing options

Calculation methods

Time division

Single zone model

Inherent heating systems

Solar heating systems

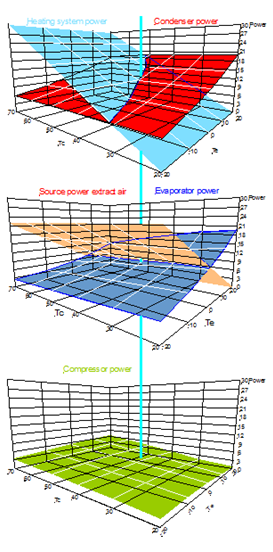

Heat pump

Default values

Compressor function

Heat exchangers

Testing standards

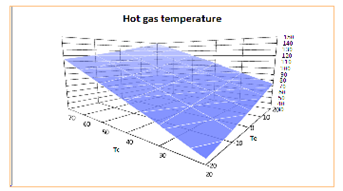

Heat gas exchanger

Energy sources

Geothermal (Rock)

Exhaust air

Ground source heat pump soil collector

Sea collector

Outdoor air coils

Heat distribution

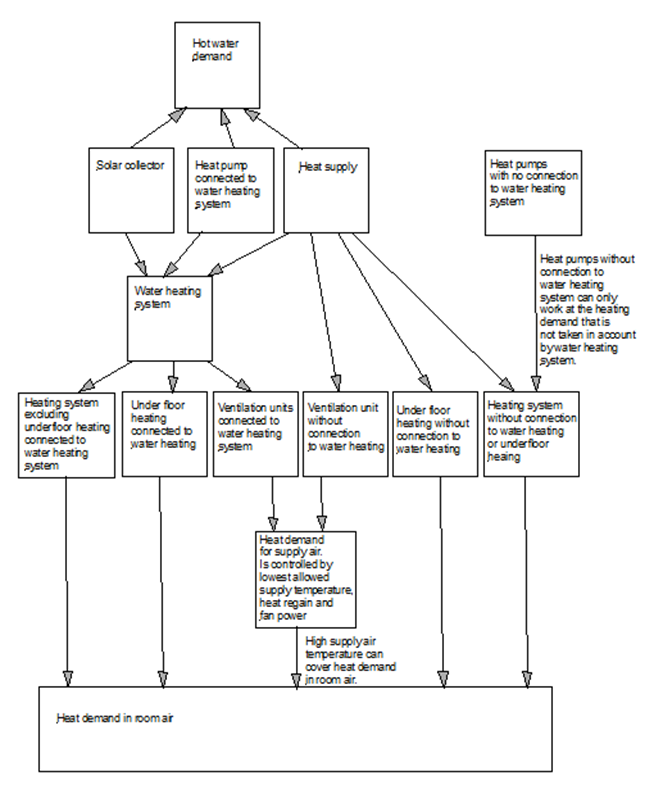

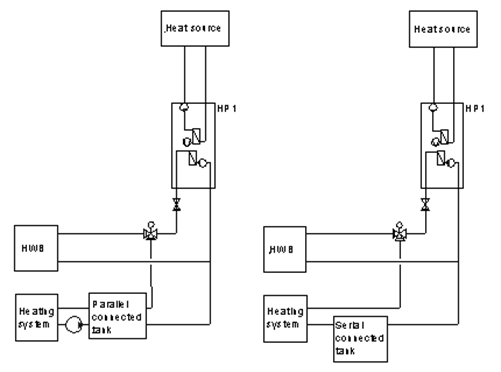

Water heating system

Air heating

Accumulator tanks

Sequence control

Energy balance

Heating/cooling

Heating

Cooling

Air system

Air infiltration

Ventilation systems

Energy recovery

VAV-system Forced air flow at cooling demand

General

Priority of cooling

Priority of forced air flow

Condensation

Limit of available power.

Recovery

Heat capacity

Process energy

Transmission

Solar radiation

Ground models

2D- and 3D models

Orientation towards ground

Result presentation

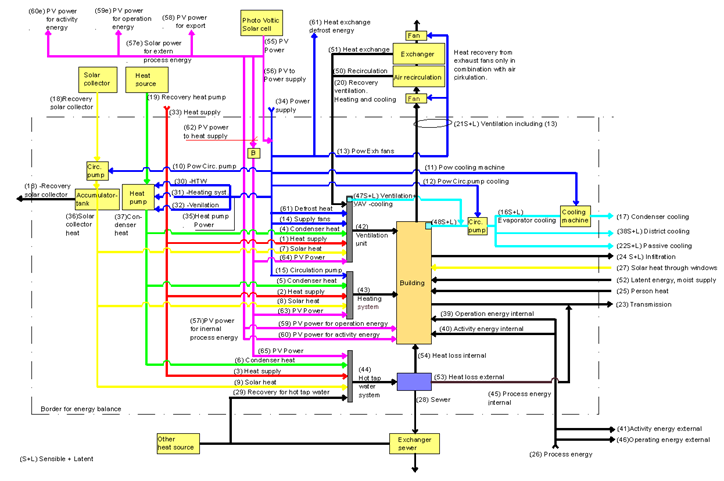

Items of the energy balance

Presentation principals

Validation mode

References

Glossary

Appendixes

Appendix 1

Appendix 2

Appendix 3 Climate

Delivered climate files

File format:

|

|

| |

|

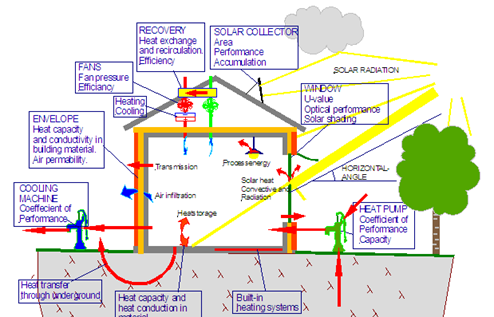

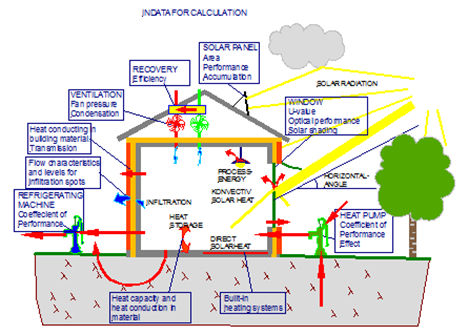

InfoCopyright: Strusoft 2020 Updated:2020-07-30 IntroductionGenericThe program calculates the energy consumption for buildings. All parts of the energy flow are calculated from known or measured facts. VIP-Energy is primarily intended for calculating the energy consumption of a building over a period of time usually covering one year but also shorter periods can be calculated. However, because the program is built around a dynamic calculation model with hourly calculation, instantaneous data for power, temperature and relative humidity are also available. 1.2 Validation The program as a whole is validated according to Ashrae 140-2007 and EN15265. Calculation functions for 2D and 3D models are validated according to ISO 10211:2007. Photovoltaic compute functions are controlled by comparison against the PV-SYST application. Examples and advice on applications This manual is limited to describing the contents of VIP-Energy. Input, result reporting, and a summary description of calculation functions. To this is a supplementary description how the program can be used in different situations. The PDF file with the description can be found under the menu "Applications" but can also be opened Here. |

|

| |

|

Data files in VIP-Energy Data for individual compute items is stored in project files with the ending .VIP. These project files contain project data such as catalog data and recent use of climate data for the individual compute object. When a user opens a project file, the application loads project data, catalog data, and climate data from that file. Therefore, there is no relationship between catalog data for different compute items. The catalog files in the catalog folder can be updated by the user choosing to export data from a project file. The catalog file update command is located under the Catalog Data menu. If catalog files contain data that is missing in a project file, that data can be imported. The "Import of Catalog Data" command is located under the Catalog Data menu. Imported data is added last to the compute object catalog. A set of latest catalog data is available on www.vipenergy.net and can be downloaded by selecting the download of catalog data under the Catalog Data menu. It works in the same way as importing catalog data. The program saves, at each calculation, temporary project files in the user's temporary files folder. Windows assigns each user a temporary files folder that is usually located under C:\Documents and settings\.......A link to that file can be found under the menu "Files". The temporary project file has the same name as the project file that the user saves but the ending. Tmp. It can be used directly if you change the "tmp" ending to "vip". Each time the user saves a project file over an existing file, the program saves the existing file with the VIPBU ending and that file is in the same folder as the project file. In cases where a project file cannot be loaded correctly, it cannot be saved or destroyed the current VIPBU file. The program contains a number of control stations at different levels for checking input. Dialog windows check the data that can be assessed for themselves. When calculating, it is verified that data from different dialogues are coordinated. |

|

|

|

Calculation guide Design building components that will be used in the project.Use VIP-Area to collect and organize amounts of building components like areas and lengths. Open Building data dialog under Project menu and import the data file saved in VIP-Area. Open Climate data dialog and choose climate file and feed micro climate data like wind protection and horizontal angle Open operation data and choose a appropriate time schedule or modify a new schedule. Eventually modify operation cases to fit the project. If there is a ventilation system open time controlled ventilation dialog and from that open ventilation control case catalog. Add a control case and set appropriate functions and values. For exhaust ventilation no functions has to be activated in normal case. Go back to ventilation window, add a ventilation unit with connected control case. Open time schedule dialog and hoose an existing time schedule for the ventilation unit or add a new one. Edit appropriate flow values. If there are some special equipment for heating or cooling those windows has to be edited otherwise they can be ignored. Calculate by opening the calculation dialog and if no error messages shows up click at calculation button. If he calculation is performed leave the dialog with OK and go to the dialogs under the result menu. |

|

| Top of page |

|

Graphical interface design |

|

Generic information |

|

By pressing the F5 key on the key board a calculation is submitted with current data wherever the user is positioned in the program. At the beginning of the calculation, data from different input windows are linked together. Names are used for identification. Only one input window can be open but all result windows can be open continuously. |

|

| |

|

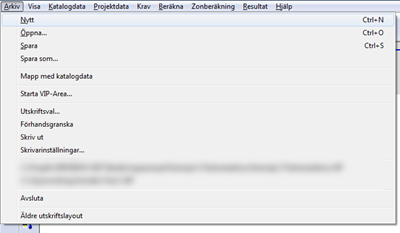

Main window The main window opens when the program starts. It contains a number of menu choices in the upper part of the window.The name of the program (VIP-Energy), the project name (decided in Title), the current file, and the active window are shown on the title row. |

|

|

|

| With the menu row, the user chooses a window by clicking on the adequate menu text. The corresponding window will open or a sub menu will be shown. Sub menus exist in several levels; the user opens the corresponding window by another click on a sub menu choice. Some menu choices can be marked in grey. This means that input data that has been indicated so far makes inadequate and the opening of the window has therefore been prevented. The tool bars in the left edge have links to input dialog windows. The tool bar in the right edge have links to result dialog windows. Files Functions for external communication with storage units, printers and some internet functions. View Settings for view of status-bar, tool-bar and program running mode. Catalog data Data that is common for different projects, like materials, building parts and technical equipments. Project data Data mostly specific for each project like size of building. Calculation sigle Calculation for a single zone like a family buiding. Calculation muliple zones Calculation for a larger building with zones with different climate properties. LEED calculation Calculation with caompaison to LEED reqirements. Results Shows the result of the calculation. Help Links to manual and license functions. Toolbars Tool bars in the main window offers direct access to the same function as menu choices. They are self instructing via the status bar in the bottom of the window and pop up tips. At program start the program version is checked and if there is a newer version an information is shown in the main window. The upper toolbar contain following buttons:  New project New project  Open existing project file Open existing project file  Save project file Save project file  Prewiev print layout Prewiev print layout

Open manual Open manual  Wiev energy map Wiev energy map About VIP-Energy… About VIP-Energy…  Starta VIP-Area program Starta VIP-Area program

Calculate directly Calculate directly  Print directly Print directly

The left toolbar contain buttons for input data dialogs: klimatdiagram  Outdoor temperature Outdoor temperature  Global horizontal radiation Global horizontal radiation  Wind sppeed Wind sppeed Relative humidity Relative humidity

Solar cells  Exposure and orientation Exposure and orientation  Catalog for solar cells Catalog for solar cells  Catalog for shading of solar cells Catalog for shading of solar cells

Building and its parts  Building Building

1-dimensionell building parts 1-dimensionell building parts  2-dimensionell building parts 2-dimensionell building parts  3-dimensionell building parts 3-dimensionell building parts

Material Material  Windows and doors Windows and doors  Control funkctions windows/doors, Solar shading, infiltration, U-vaule Control funkctions windows/doors, Solar shading, infiltration, U-vaule

Operating cases  Time schedule Time schedule  Catalog Catalog

Energy supply  Equipment for heat supply Equipment for heat supply Equipment för supply of comfort cooling Equipment för supply of comfort cooling

Temperature controlled ventilation Temperature controlled ventilation  Time controlled ventilation Time controlled ventilation

Energy prices Energy prices

Demands connected to BBR Demands connected to BBR

Right toolbar contains buttons for resultat dialogs and diagrams.  Pie diagram supplied energy Pie diagram supplied energy  Emmitted energy Emmitted energy

Chart diagram for energy balance Chart diagram for energy balance Duration diagram Total energy balance Duration diagram Total energy balance

Room temperature Room temperature Operative temperature Operative temperature  Exhaust air temperature HP Exhaust air temperature HP

PPD-Index summer climate PPD-Index summer climate

Time devidesd energy balance Time devidesd energy balance  Total energibalance Total energibalance

Key value Key value

Energy supply Energy supply

Solar power Solar power

Comparison to demands Comparison to demands

Costs Costs

Custom report Custom report

Export of data to text file Export of data to text file

|

|

|

|

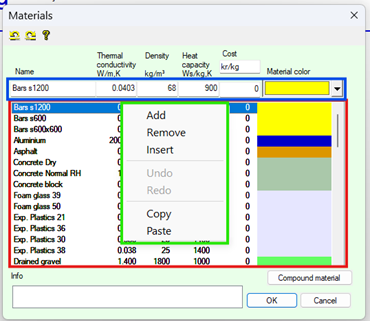

Generic input window laout The user communicate with the program via input windows which can be reached via menu choice in the main window or icons in tool bars. With the  button the user can regret measures and with the button the user can regret measures and with the  button is it possible to go forward again. button is it possible to go forward again. Some input windows contains a list box (Red frame) and edit boxes(Blue frame). By clicking at a line in the list box data is copied up to corresponding edit boxes. By editing data the list box is simultaneous updated. By right mouse button click in the list box an context menu shows up (green frame). By clicking at add, delete or insert lines are controlled. Even the delete key at keyboard can be used to delete a marked line in the list box. A line can be moved by keeping left button down and drag the line to a new position. The Copy and Paste functions make it possible to copy data from one project to another. In several input windows there are buttons with links to other windows. In this example Compound material window can be reached from material window. |

|

|

| |

|

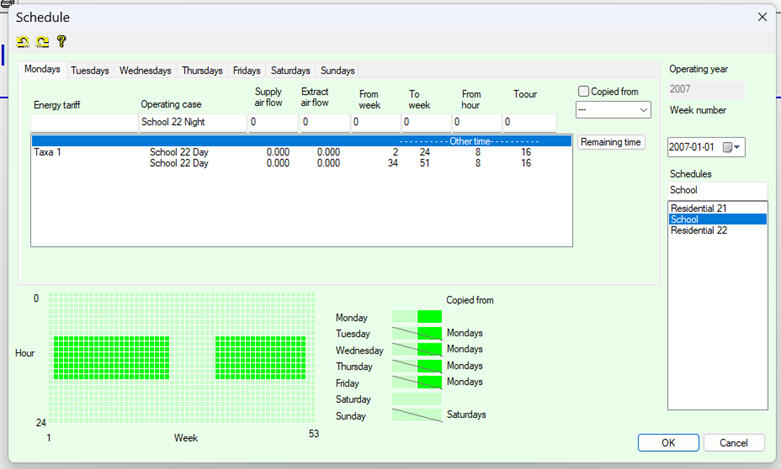

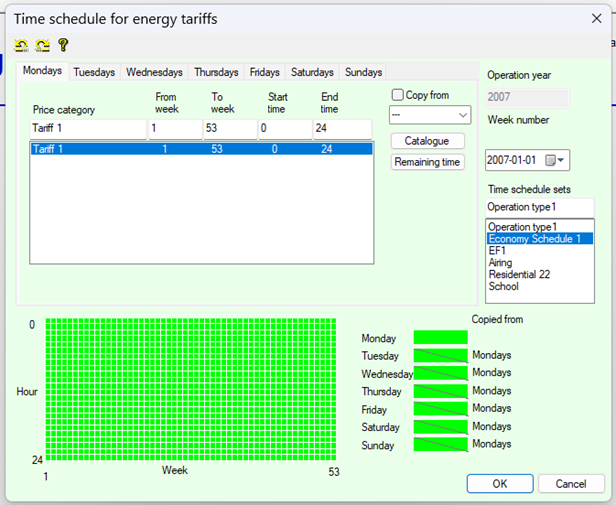

Time schedules Time schedules for operation, ventilation and energy costs are saved in catalog data. The catalog can contain a number schedules for different type of activities. Each schedule can keep data for operation case, ventilation flows, and energy prices. It also possible to use separate schedule for operation, ventilation and prices. |

|

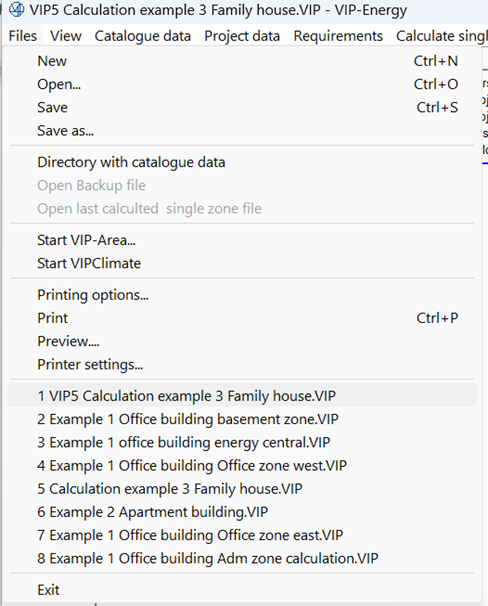

Files |

|

|

|

New Project data will be erased and default catalog data will be loaded. Open Collect a previous stored project file. Save Save a project file with the current filename. The user must earlier have defined a file name under Save as. Save as Define a filename for a project file. Directory for catalog data A link to the directory where files whith catalog data, climate, and copy files are stored. Open Backup file Opens the directory where VIPBY files are located. Open last calculated single zone file Opens the temp directory that contains an extra backup file Start VIPArea Open the VIP-Area program. Start VIPclimate Starts an app that convert data til vipclimate format. Printing options Defines what is to be printed. Print Send to printer. Preview Preview printing before printing. Printer settings Choice of printer and settings of printer parameter; for example print-out quality. Exit Exit the program. |

|

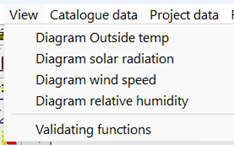

View |

|

The option "Validating functions" open up input data windows that are used in the case |

|

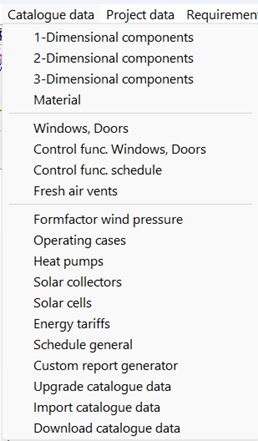

Catalog data |

|

|

When starting a new calculation, default catalog values from common catalog files will be fetched. After that every project gets individual catalog values. A change in catalog values in a project will therefore not influence other calculations. Unreasonable values will be checked automatically. |

|

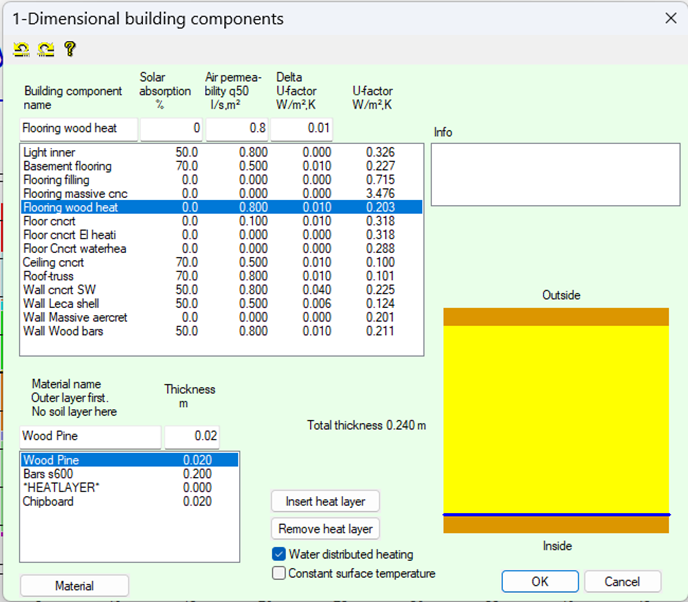

1-dimensional Building component |

|

|

|

| The menu item Building component catalog- 1-Dimensional building component are used to specify material composition, solar absorption, density and U-value. Walls, joists, roofs and floors of the building with one-dimensional heat flows are defined in this catalogue. The building components are in the order in which the user selects. It is not possible to define two building components with the same name, but you can have the same material name in a building component more than once. For building components with orientation INNER , Solar absorption, U-value (D-U value) and air permeability are not necessary for the calculation. The U-value does not include the D-U value Add new building components Right-click the list and choose Add or Insert. The program gives the new building component the same structure as the existing marked building component. Then you can revise the new building component. Copy/Paste With the right click on the top drop-down list, you will see a menu where you can choose to copy out a building component to a file "1DPart.vipcopy" that is placed in the folder for catalog files and climate files. The building part can then be pasted to other projects. Material layers building components with orientation "INNER1", energy flow to room air is calculated through the material surface of the last given material layer. For building components with orientation INNER2, energy flow is calculated through both material surfaces. The U-value in the building component list is updated for each material that is added. The materials in the building component must be defined in the material catalogue before calculation can be carried out. Material names can be entered by hand on the input line, but are advantageously retrieved by clicking on the Material Catalog command button, displaying a dialog box with a drop-down list containing all the materials defined in the material catalog. In the meaterial catalog list, you select which material you want to use, and press OK, and the selected material is copied into the input line in the correct place in the building component directory. The thickness is given manually. The user determines the order in which the building components are in the list. The program does not sort in alphabetical order. It is not possible to define two building components with the same name, but it is possible to have the same material name in a building component more than once. If a selected material does not exist in the material catalog, it is written in parentheses. In these cases, no U-value is written for the current building component. More information about the material dialogue can be found under the heading Material. Heat layers The program includes a function for simulation of built-in heating systems e.g. underfloor eating. In each building component you can insert a heat layer used for simulation heating pipes or electric-heating cables. The temperature in the heating layer can be regulated according to heating needs or with constant surface temperature. When regulating with regard to heating requirements, the "Building" dialogue indicates the proportion of each building component to provide of the total power requirement. This then provides the basis for calculating the required temperature in the heating layer. When regulating with regard to constant surface temperature, the "Building" dialogue indicates the surface temperature in the adjacent temperature column. To insert heat layers into a building component, press the Insert heat layer button. A heat layer is then inserted where the cursor is located. Use Remove heat layer to remove it. The check box for water-borne heat means that the building component is connected to the water heating system and can be fed from heat pumps connected to water-borne heat. U values Any changes made to the material list will cause an update to the U-value of the building component. There is an association between this catalog and the Input Building menu option, which means that any changes made to catalog data affect project data. For example, the U-value is also updated in the input dialog Building when changing e.g. thermal conductance. The program sets external and internal heat transfer resistance to 0.04 and 0.13 m²K/W respectively. D-U values Delta-U values can be used to adjust the U-value resulting from the thickness and thermal conduction ratio of the material layers. The program adjusts the heat conduction ratio of the materials taking into account the adjusted U-value. Material layer image The materials can be assigned to colors used in drawing the figure. Solar absorption Absorption coefficient of solar radiation to the outside of the building component. Total reflective white surface has value of 0 % Total absorbent matte black surface value 100 % Normal value for walls is 50-70 % Black roofing paper has about 90 % in absorption. Permeability factor q50 Air leakage of the building component in l/s, m2 at 50 Pa pressure difference. Normally the value is between 0.4-0.8. If extra measures are taken, it may be lower and if it is higher there will usually be comfort problems. Air gaps The program has no function to directly specify heat resistance for air gaps, but this may be converted into a thermal conduction number that becomes specific to each layer thickness. Air gaps are normally only inserted if they are not ventilated against outdoor air. In structures, air layers are normally ventilated against outdoor air. For non-ventilated layers, heat resistance and heat conduction ratios as shown in the table below can be used.

| Layer thickness [m] |

Thermal resistance [m²K/W] |

Thermal conductance [W/m] |

| 0,005 |

0,1 |

0,05 |

| 0,01 |

0,13 |

0,077 |

| 0,02 |

0,15 |

0,133 |

| 0,05 |

0,16 |

0,313 |

| 0,1 |

0,15 |

0,67 |

Limitations:

| Value: |

Min: |

Max: |

Unit |

| Absorb coeff: |

>=0 |

<=1 |

|

| D-U-value: |

>-U-value |

<=1 |

W/m2C |

| Infiltration: |

>=0 |

|

l/m2s |

| Thickness: |

>0 |

|

m |

|

|

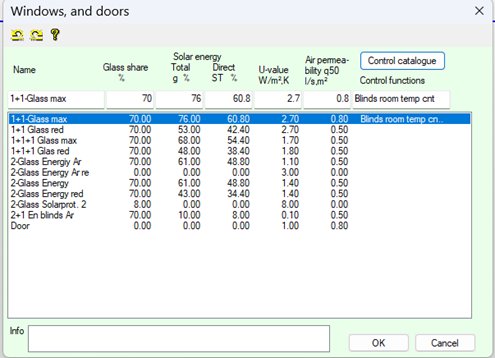

Building component windows, doors |

|

|

|

| General Parameters for windows, doors and parameters for Glass share, Transmittance, U-value, Air permeability and Shading. Information on solar transmittance is in the appendix or can be fetched from glass manufacturer. TST is the share of the external radiation that reaches the room. ST is the share of external radiation that reaches the room as radiation. The remaining quantity reaches the room as convective heat. Add new building component Right-click the list and choose Add or Insert. The program gives the new building component the same structure as the existing marked building component. Then you can revise the new building component. Copy/Paste With the right click on the top drop-down list, you will see a menu where you can choose to copy out a building component to a file "WDOPart.vipcopy" that is placed in the folder for catalog files and climate files. The building comonent can then be pasted to other projects Glass share The value indicates the proportion of the total space made up of glass. It affects the amount of solar energy through the window. Solar transmittance Information on solar transmittance can be found in Appendix 1 or can be obtained from glass manufacturers. Total transmittance indicates the percentage of heat that goes through the glass and is denoted in literature as usually g or TST. Direct transmittance indicates the proportion that reaches in the form of direct radiation to the interior surfaces of the room. The remaining amount reaches the room as convective heat to the room air. Normally, 70 % of the g-value specified by glass manufacturers is indicated to take account of normal sun protection measures such as blinds and curtains. Doors To define a door, set the values of solar transmittance to zero (0) Limitations:

| Value: |

Min: |

Max: |

Unit |

|

| Glass share |

>=0 |

<=100 |

% |

|

| Total transmittance |

>=0 |

|

% |

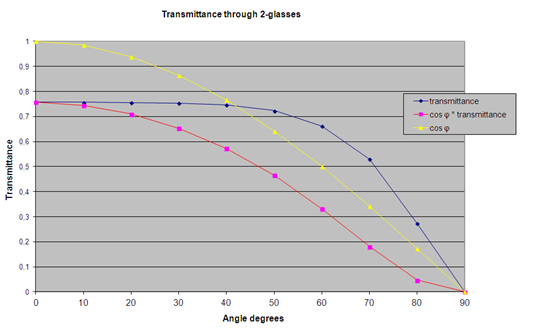

[Enclosure 2] |

| Direct transmittance |

>=0 |

|

% |

[Enclosure 2] |

| U-value: |

>=0 |

|

W/m2C |

|

| Infiltration: |

>=0 |

|

l/m2s |

|

|

|

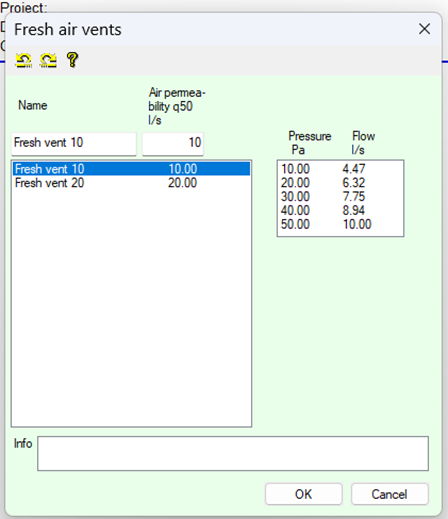

Fresh air vents |

|

|

|

General This dialog defines catalog data for outdoor air vents and other leaks that should not be assigned to an area. Outdoor air vents do not count towards the climate shell permeability when compared to requirements for leaks. Input is given for the airflow at 50 Pa pressure difference. Such large internal suppression is unusual and in the table the flow has been calculated at lower pressures. Normal internal suppression in exhaust air vented buildings is 10-20 Pa. |

|

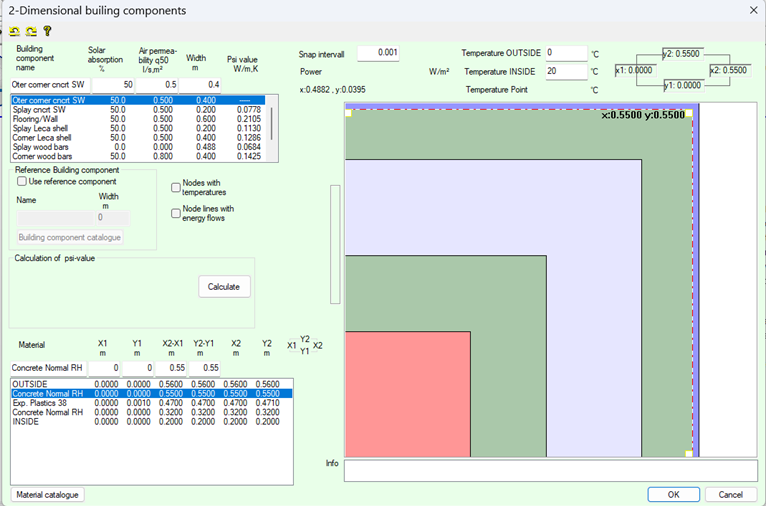

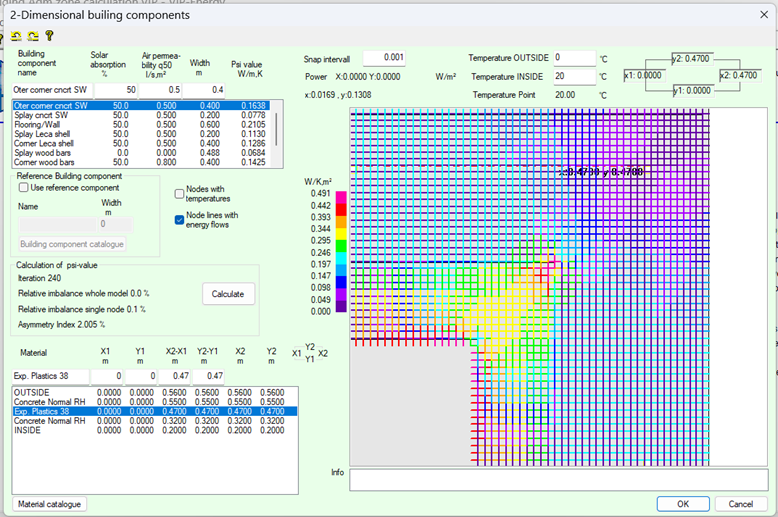

2-dimensional building component |

|

|

|

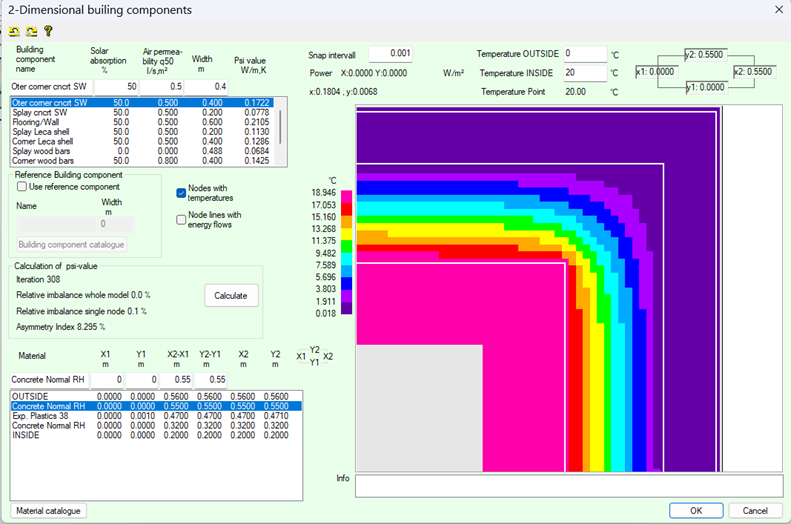

| VIP Energy contains a calculation function for 2-dimensional building components. The figure example shows a corner in a concrete sandwish wall. 2 dimensional building components are used and quantified the same way as the 1 dimensional ones except that quantity is in m instead of m2. The width is only used in combination with the length to calculate the envelope area for the building. Build the model by entering X- and Y- coordinates for each material in the construction. External and internal air is entered by reserved names OUTSIDE and INSIDE, marked as blue and red fields. The thickness of the 2D-model in z direction is always 1 m. For the U-factor calculation the program enters the inside and outside heat transfer resistance to 0, 13 and 0, 04 m²K/W. The model is drawn in a graphic window when the values are entered. Click on one point in the picture and the pictures coordinates are being transferred to an in data dialog. Snap interval can be set to minimum 0,001 m, which means that the coordinates is transferred in millimeter. A snap interval of 0, 01 means that coordinates are transferred in even centimeters. When clicking on Calculate the specific heat flow is calculated trough the model and is presented as a psi-value W/mK There are two alternatives for using 2-dimensional building parts in calculations. Alternative 1: The program creates an equivalent material and displays thermal conductivity, heat capacity and density that are used in energy calculations. The total energy flow is presented as a Psi-value. Alternative 2: If the user assigns a 1-dimensional building componnt as a reference then the program calculates the difference between the 1-dimensional component and the 2-dimensional component. The difference is presented as a Psi-value. If alternative 1 is used without a reference value then the 2-dimensional building part is handled like an ordinary wall with heat capacity. If alternative 2 is used then the program handles the building part in a simplified model just like doors without heat capacity. The program calculates an asymmetric index as a measurement of the model´s asymmetry towards the borders that are supposed to be symmetric lines. Symmetric lines are the borders where the model is not connected to inside or outside air. Energy flows are supposed to be natural parallel to the borders but if the model is too small the model forces flows to be parallel. An asymmetric index should be less than 5% for the model not to be affected by a narrow cut around the 2- dimensional areas. |

|

|

|

| When Node lines with energy flows are checked the program shows calculated node lines with colors that represent energy flows quantities in W/m2. The scale is divided in ten colors. |

|

|

|

| When Node with energy temperatures are checked the program shows calculated temperatures in a scale from from outside to inside temperatures which is specified by the user. |

|

| |

|

|

|

3-dimensional building components |

|

|

|

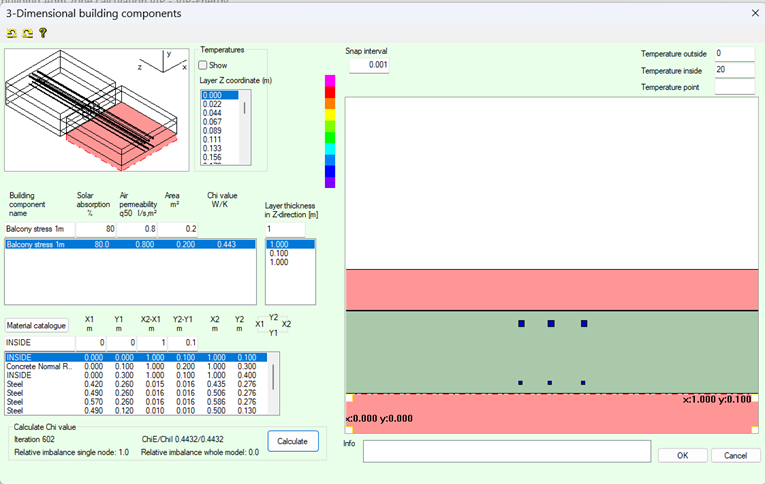

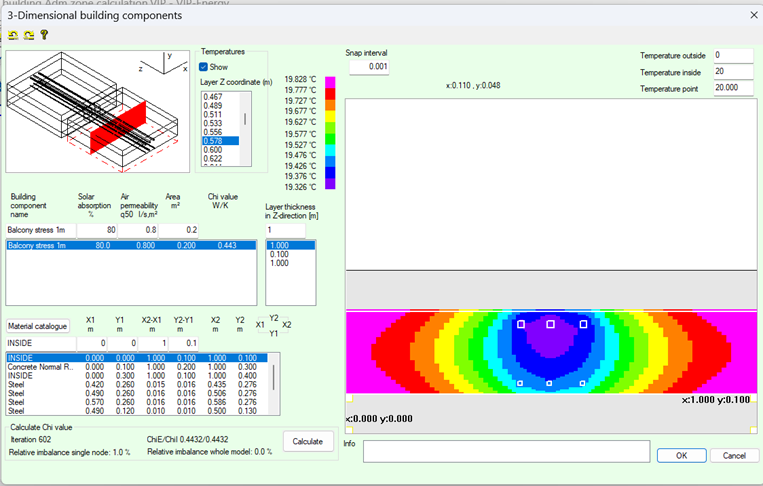

| The figure shows a balcony connected to the slab with reinforced concrete partly broken by insulation. 3 dimensional components is used for specifying material and solar absorption; air permeability and U-value that sometimes known as thermal bridges. The area value is used for calculating the total envelope area. 3-dimensional components are used as a 1 dimensional components with the exception that it is the number of units that are calculated instead of m2 Material is retrieved from the material database. The model is built up by entering X, Y and Z coordinates for the material in the construction. Outside and inside air is entered by the reserved names OUTSIDE and INSIDE, marked as blue and red fields. For the U-factor calculation the program enters the inside and outside heat transfer resistance to 0, 13 and 0, 04 m²K/W. The graphical display is drawn when material is added to the construction. Click in the picture and the coordinates in that picture are transferred to an in data list and edit windows. A 3-dimensional picture is also drawn when material is edited. This upper left 3D picture is for information only and the content cannot be edited or selected in this picture. The calculation is done for the visible parts of the material. Material can be overlapped in each layer. The total energy flow through the model is presented as a Chi value W/K. |

|

|

|

| When Temperature is checked, the program shows calculated temperatures with colours that show the temperature in each section. When clicking on Calculate the specific heat flow is calculated trough the model and introduced as W/K. |

|

4.6.6. Control functions for solar protection, air permeability, U value |

|

|

|

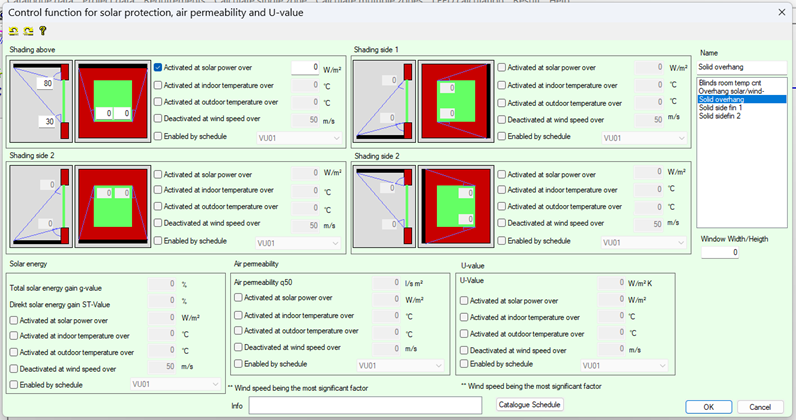

| General The control functions are used for the building components in the Window/Doors catalogue. It is a catalogue of control functions for sun protection U values and permeability factor, as well as associated control parameters. At least one of the conditions for room temperature, outdoor temperature or solar power against façade shall be met to activate the control functions. It is solar power perpendicular to the window referred to. If the wind speed exceeds the set value, the control function is disabled. If this feature is enabled, values in the control catalog apply. Otherwise, values in the window/door catalog will apply. Add new control function Right-click the list and choose Add or Insert. The program gives the new record the same build up as the existing selected record. The new directory entry can then be revised. Copy/Paste With the right click on the top list, you will see a menu where you can choose to copy out a control function to a file "WDOControl.vipcopy" that is placed in the folder for catalog files and climate files. The control function can then be pasted to other projects. Screens Screens are used to simulate moving sunshades such as awnings and fixed as balcony plates. To simulate fixed screen, it is easiest to activate it with solar power and the value is set to 0 W/m². Solar transmittance Used for sunscreen simulation that covers the entire window and is independent of angles. The value refers to total transmittance for sunscreen and windows. It is independent of the transmittance of the window without sunscreen. Permeability factor The most nearby application is simulation of airing. U value In some cases, the choice of sunscreen also affects u-value. For example, blinds between windows usually contribute to reducing the U-value |

|

| Limitations:

| Value: |

Min: |

Max: |

Unit |

|

| Shield angle: |

>0 |

<180 |

degr |

|

| Wind speed: |

>=0 |

|

m/s |

|

| Transmittance |

>=0 |

|

|

|

| Air permeability |

>=0 |

|

|

|

| U-factor |

>=0 |

|

|

|

| Solar power |

>=0 |

|

|

|

|

|

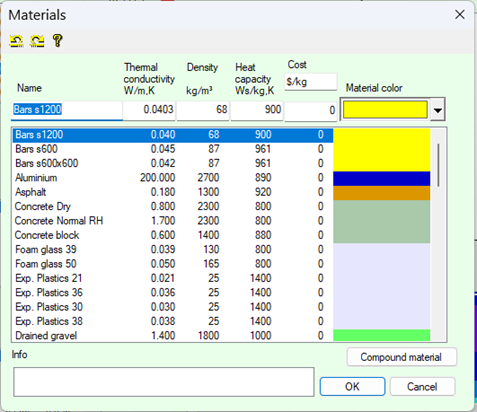

Material catalog |

|

|

|

| General The Material Catalogue specifies materials of which the building components in catalogue 1-, 2- and 3-dimensional componenst are constructed. Add new material Right-click the list and choose Add or Insert. The program gives the new material the same structure as the existing marked material. you can revise the new material. Copy/Paste With the right click on the list, you will see a menu where you can choose to copy out a material to a file "material.vipcopy" that is placed in the folder for catalog files and climate files. The material can then be pasted into other projects. Thermal conduction ratio Thermal conduction ratios are sometimes also called lambda value and indicate the thermal conductivity of the material. Density and heat capacity The calculation uses density and heat capacity to calculate the building's heat storage capacity. Density can usually be retrieved from data sheets for materials. Data on heat capacity that is more dependent on the base material can be obtained from building manuals. Material cost The material cost can be given any unit but is always linked in the calculation to the material weight. This function can be used to calculate economy, environmental impact such as the amount of CO2. Material colour Material colour is used to define colors that are used when drawing shapes in building part catalogs or in result printouts. The color dialog contains a number of standard colors and with the narrow button at the bottom of the dialog, a dialog window is reached where any color can be selected. Limits:

| Value: |

Min: |

Max: |

Unit |

| Thermal conductivity |

>0 |

|

W/mC |

| Density: |

>0 |

|

kg/m3 |

| Heat capacity: |

>0 |

|

Ws/kg |

|

|

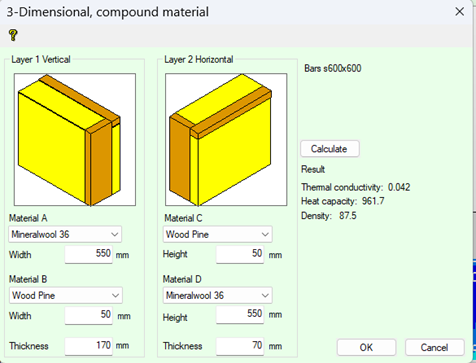

Compound material |

|

|

|

| General The function is used for 3 dimensional calculations of resulting composed material properties in building componens with two material layers in two directions. A description is made for a composition that consists of one or two layers. Each layer contains two materials where the user chooses type, width and height of a material. Calculation Pressing the” Calculate” button the thermal-conduction, heat-capacity and density will be calculated. The OK-button is activated when the calculation is finished. If ending the dialog with OK, the calculated values and inputs will be stored in the material that was marked in the material list when the dialog was opened. Current composed material is to the top the dialog window. Width and height must always be larger than zero though a thickness of a layer can be zero. Example The figure below shows a stud wall with standing and lying studs. The calculation is performed on a representative part. The boundaries are drawn in symmetry lines where the heat flow runs parallel through the wall. The example shows the smallest slicer needed for a calculation. A half compartment of the width and height has been included. It will be the same result as bringing a whole wall.  If the wall has only standing studs, you take with an arbitrary height and select the thickness of layers two to 0 mm. Sheet metal profiles The figure shows a sheet metal profile, stud or runner. It can be replaced with a solid profile with the same dimensions and with material data that gives the same thermal conductivity as the sheet metal profile. For slotted steel profiles, the thermal conductivity is dependent on the design of the slots and the manufacturers' accounting of characteristics is referred to. There is rarely data for individual profiles that can be directly used in calculations, but for some brands there is data on U-values for individual design types. From this, thermal conduction rates for individual profiles can be derived. The table below shows the thermal conductivity W/m K for profiles with profile width 145-250 mm and plate thickness 0.7-1.5 mm. Data applies to normal studs and runners. Profile width is the same measure as layer thickness in input. For special profiles, such as reinforced studs, the value may be higher as these may be less slotted. There is generally a lack of data, but one estimate is that thermal conduction rates should be doubled for those types of profiles.

|

Plate thickness mm |

Profilw width mm |

0,7 |

1,0 |

1,2 |

1,5 |

145 |

0,11 |

0,13 |

0,16 |

0,18 |

170 |

0,12 |

0,15 |

0,17 |

0,19 |

195 |

0,14 |

0,17 |

0,2 |

0,23 |

250 |

0,16 |

0,19 |

0,24 |

0,3 |

The fact that the thermal conductivity increases for increased plate thickness feels natural, but it also increases for increased profile width and insulation thickness. It is likely to depend on the design and amounts of the slots. The density of the material is set at 7800 [kg/m³]*sheet thickness [mm]/50. The heat capacity is not affected but is the same as for solid material. If the design of the slots is known, it is possible to use the 3D function of the program to calculate the thermal conductivity for specific products. Sheet metal studs without slots are less complicated and can be calculated based on sheet metal thickness. For steel studs, the thermal conduction ratio is set to 60 [W/mK]*sheet thickness[mm]/50. The material is then used in for the calculation of composite materials. Limitations

| Width |

<100 |

| Height |

<100 |

| Layer thikness |

>0 |

|

|

|

|

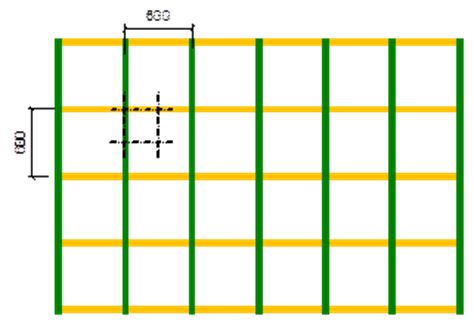

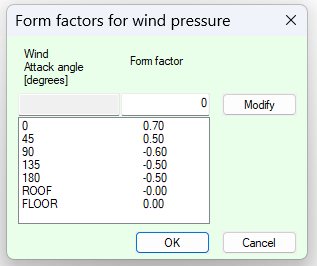

Form factors for wind pressure |

|

|

|

| |

|

Generic |

|

| This dialog is used for editing wind pressure form factors. Form factors affect facade wind pressure which is one of the parameters when calculating air leakage. The angle of incidence is the angle between the wind direction and the orientation of the surface. It is not possible to delete or add an angle of incidence. A 0° angle of incidence refers to wind on the surface. A wind direction of 180° means that the surface is completely sheltered from wind. Roofs have a form factor of their own. |

|

|

|

Standard value

| Orientation |

Form Factor |

| To windward |

0,7 |

| Leeward |

-0,5 |

| Sides parallel to the wind direction |

-0,6 |

| Roof |

0 till -0,2 |

|

|

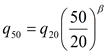

Calculation of wind pressure |

|

| Pv=FF*Pd Pd=*v2/2 Pv Wind pressure [Pa] Pd Dynamic pressure [Pa] FF Form Factor Air density [kg/m3] |

|

| |

|

Using catalog dataThe orientation of the building parts are set in In data>Building and that in combination with climate data determines the wind pressure for the building component. |

|

| |

|

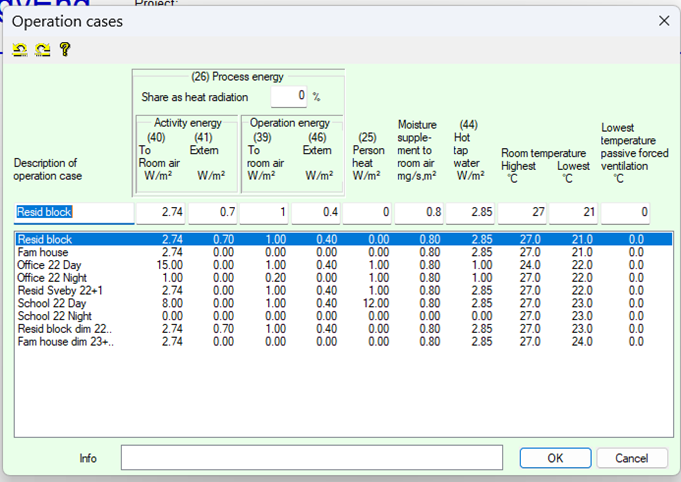

Operation cases |

|

|

|

| |

|

| General Operating cases are used to specify process energy, person energy, moisture supplements, thermostat settings for the maximum and minimum values of the room temperature, thermostat setting for passive force of ventilation and energy for hot tap water. Add new operating case Right-click the list and choose Add or Insert. The program gives the new operational case the same structure as the existing marked operating case. Then you can revise the new material. Copy/Paste With the right click on the top drop-down list, you will see a menu where you can choose to copy out a building part to a file "Operationcase.vipcopy" that is placed in the folder for directory files and climate files. The building part can then be pasted to other projects. Process energy Process energy is energy use that is controlled by the activity regardless of climate requirements. Activity energy to room air and operation energy, is treated in the same way in the calculation, but the breakdown is conditioned by how the amounts of energy are to be valued when calculating specific energy use according to BBR. Operation energy is included in specific energy use to be compared with requirements. However, activity energy does not. Of the activity energy, and operation energy, some can be specified to go to room air and some to be emitted externally without the influence of the construction energy balance. The user can control whether process energy should be supplied as radiation to building parts or convectively to the room air. Normally, all energy is added convectively to the room air and the proportion of heat radiation is set at 0%. Person energy Person energy is supplied to the room air in parallel with activity energy and operation energy. The difference is that person energy is not included in the calculation of energy costs. Moisture supplements The value indicates moisture supplements to the room air. The moisture content affects the recovery of heat from exhaust air with exhaust air heat pump and cooling functions associated with return air. Moisture supplements can condense and freeze to ice in plate heat exchangers if calculation is carried out according to EN308. Evaporation and condensation of moisture are presented in results as latent energy. Evaporation heat for moisture at room temperature is 2500 kWs/kg. Example: Normally, 2 g/kg of moisture is added to the room air in homes. This applies to standard ventilation 0.35 l/sm² and normal person density. The volume flow of 0.35 l/s,m² corresponds to the mass flow 0.42 g/s,m². To reach 2 g/kg, the moisture input is set to 0.84 mg/s,m². Hot tap water The program sums up the amount of energy for hot tap water that is part of the energy demand. Energy for hot tap water is not supplied to the room air, but is released entirely as waste water. Room temperatures The hours room temperature tend to go below the minimum temperature heat is added. The hours of room temperature tend to go above the maximum allowable temperature cold is added. Minimum temperature can be adjusted to take account of regulation losses in the dialogue Heat supply. The lowest and maximum temperature values are the temperatures that will occur in the building. As a rule, the minimum temperature is slightly higher than the minimum permissible temperature due to incompleteness in control functions. This applies specifically to regulation with self-acting thermostatic valves on radiators that need some degrees temperature rise to close completely. Normally, an increase of the minimum room temperature of 2 °C should be sufficient to cover incompleteness in thermostatic valves. Electronic regulation can be made more precise. When calculating underfloor heating, the program simulates the control inertia of floor heating and the user only needs to take into account the incompleteness of the regulated area. Minimum temperature passive force The value indicates at what room temperature passive force can be activated. In order for activation to take place, the other conditions specified in the dialogue for temperature-controlled ventilation must also be met. Use of catalog data Under Project data>Operation Temp/process energy, operational cases are put into a time schedule. Limitations |

|

| Value: |

Min: |

Max: |

Unit |

| Max temp: |

>=Min temp |

|

C |

|

|

|

|

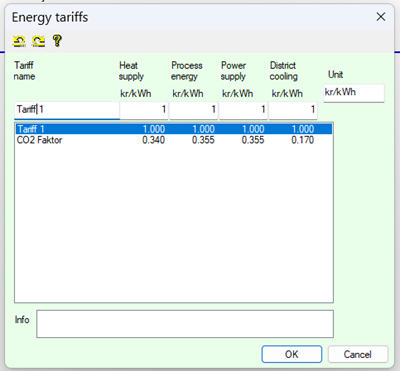

Energy price |

|

|

|

| Various energy rates can be told for: Heating of room, inlet air and hot water. Process energy Electric energy for heat pumps and fans. District cooling In order to specify combinations of rates for different energy types. The user chooses the type which for example can be kgCO2/kWh.

If /kWh exists in the unit, it will be taken away when the cost is presented. Then there will be a presentation in dollar or kg CO2 only. |

|

|

|

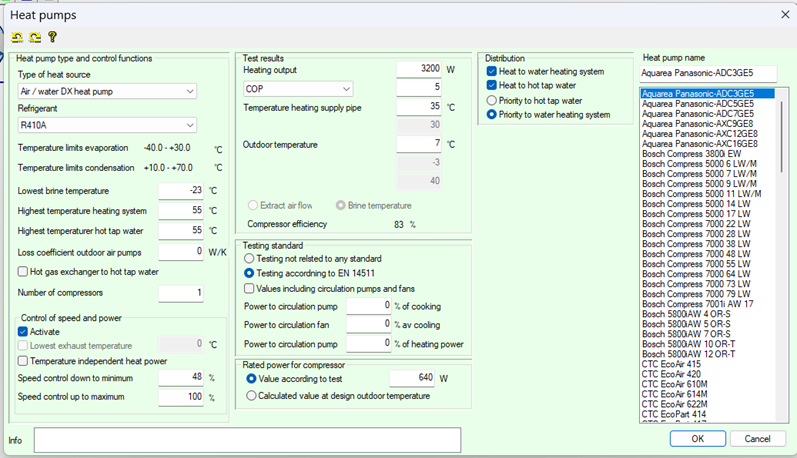

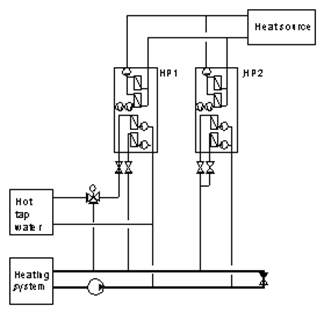

Heat pumps |

|

|

|

| The dialog is used for creating a catalog for heat pumps that can be used under In data>Heating & Cooling. |

|

Type of heat sources |

|

| VIP-Energy consider 8 types of heat sources: Exhaust air Gets heat from exhaust ventilation flows. Gives heat to water heating system. Geothermal, Rock Gets heat from rock holes. Gives heat to water heating system. Ground source Soil Gets heat from collector pipes in soil. Gives heat to water heating system. Sea heat Gets heat from collector pipes in sea water. Gives heat to water heating system. Air/Water DX Gets heat from fan coil out door. Gives heat to water heating system. Air/Air Gets heat from fan coil out door. Gives heat to fan coil in room air. Air/Water Brine linked Gets heat from fan coil out door. Gives heat to water heating system. Exhaust air/Supply air Gets heat from exhaust ventilation flows in the ventilation unit it is linked to. Gives heat to supply air in the same unit. |

|

RefrigerantData sheets contain what type of refrigerant they use. |

|

| |

|

Highest / Lowest temperature The heat pump works within those limits. Otherwise it will shut off. |

|

| |

|

Loss coefficientFor some of the outdoor heat pumps water heating system is connected to the outdoor unit. That results in some extra losses from the water heating system. |

|

| |

|

Hot gas exchangerSome heat pumps has an hot gas exchanger that recover the hot gas from the compressor to hot tap water even during the time when the compressor deliver condenser heat to the water heating system at a lower temperature. |

|

Control of speed and power

For some heatpumps it is possible to vontrol compressor speed an power whithin sertain limits.

For some exhaust air heat pumps it can even be possible to control speed depending on exhaust air temperature in purpose to avoid frost generation in the evaporator. |

|

DistributionThe heat pump can be connected to the water heating system and the hot water system. The connection between the water heating system and ventilation units, radiators and underfloor heating system is specified in catalogs for each unit. |

|

| Share of space heaters linked to water heating system A portion of the power demand for space heating can be supplied from underfloor heating systems. Depending on the selected minimum supply air temperature, part of the power demand can be taken care of by the supply air. Remaining power demand for space heating is taken care of by space heaters or Air/Air heat pumps. Space heaters can be radiators, convectors, fan convectors, air heating systems etc. Some of these space heaters can be connected to the water heat heating system, others may be electric heating, stoves etc. Input for "Share of room heaters linked to water heating system" specifies how much of this remaining power needs to be taken care of by space heaters that are connected to the water heating system and thus can be reached by heat from the solar collectors and heat pumps and associated with water heating systems. If the share connected to water heating system is less than 100%, there is a space for air/air heat pumps. The share of power demand that are not covered by water heating system or Air/Air heat pumps are not defined and can be electric heating-heaters, fireplaces, etc. See more about heat pumps under Chapter 6.5 |

|

Test results and test standardsHeat pumps is usually tested according to at least one of the standards EN 14511. Test results is used for input to VIP-Energy. Power to pumps and fans can be included or excluded in test results. |

|

|

|

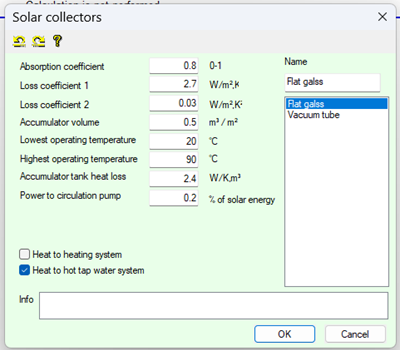

Solar collectors |

|

|

|

|

| |

|

GenericSolar heating is calculated considering input data in the form of solar radiation from climate file, horizontal angle, the orientation and inclination of the solar collector. |

|

Absorption coefficientThe value states how big share of the radiated solar energy that will be absorbed. The program calculates how big share that will be prevented and reflected by the glass surface. |

|

Loss coefficient 1The value states, together with loss coefficient 2, the heat emission from the solar collector to the surrounding air due to the temperature difference. Unit: W/m2K |

|

Loss coefficient 2The value states, together with loss coefficient 1, the heat emission from the solar collector to the surrounding air due to the temperature difference. Unit: W/m2,K2. |

|

4.6.11.1.4. Accumulator volumeThe solar heating system has a separate accumulator tank to store heat. Input for volume is m3 per m2 collector area. |

|

TemperaturesInput for temperature limits within the system can work. At tank temperature under the span no energy is delivered to the system. Heat is stored up to the upper limit. |

|

Circulation pump powerThe circulation pump is working when the accumulator tank is loaded from the collector. The pump energy is calculated on loaded energy not delivered from the tank to the building. |

|

Accumulator simulation model (Only available in validation mode)In normal case the detailed simulation model is used. The model optimize the recover regarding temperatures in heating system and cold and hot water temperatures. The simple model is used for validation of calculation at certain temperatures. |

|

Solar cells |

|

|

|

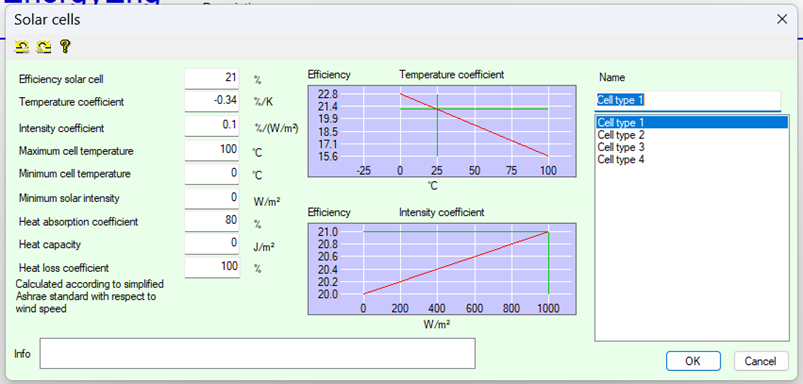

GenericThe dialog is used to specify the properties of solar cells that are used in Project data Solar cells-> Exposure EfficiencyThe efficiency indicates the proportion of incoming solar power which is converted into electricity in solar cells. The value applies to cell temperature 25 ° C and solar power 1000 W perpendicularly towards the solar cell. Temperature coefficientsThese coefficients indicates how the efficiency changes with the cell temperature. Coefficient 1 is working directly proportional to temperature change and Coefficient 2 to the square of the change. Intensity coefficient The coefficient indicates how the efficiency is affected by solar radiation intensity. Highest and lowest cell temperature The values specify the maximum and minimum temperature the solar cell to function. Outside this temperature range no electricity is produced Heat absorption coefficient The value indicates the percentage of incoming solar energy absorbed and converted to heat at the cell surface. Heat capacity Solar cells can be given a heat capacity that slows the temperature change by the change in impact. Heat loss coefficient The value specifies emitted heat in relation to normal heat emission from one side. |

|

| |

|

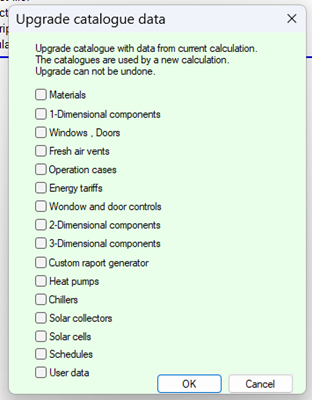

Upgrade catalog data |

|

|  The dialog can be used for upgrading the catalogs that are used for starting new calculations. The catalog (or catalogs) that is going to have the same values as the current calculation is marked in a check box. The dialog can be used for upgrading the catalogs that are used for starting new calculations. The catalog (or catalogs) that is going to have the same values as the current calculation is marked in a check box.

|

|

| |

|

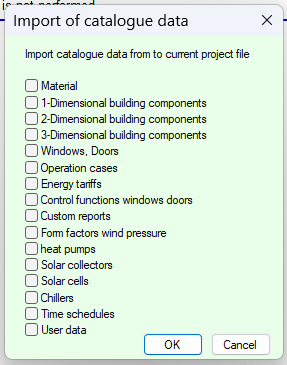

Import catalog data |

|

|

The dialog can be used for importing data from catalogues. Data that does not exist in “current data” is imported to the end of the list. |

|

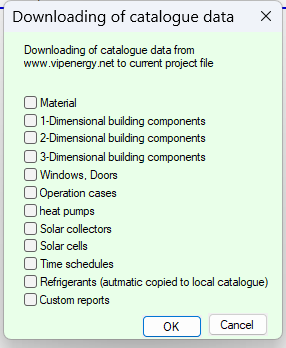

Downloading directory data from vpd files on www.vipenergy.net  This feature is similar to Directory Data Import, but in this case, data is retrieved from files located on the www.vipenergy.net. In this feature, data types that are normally created by users have not been included. |

|

|

|

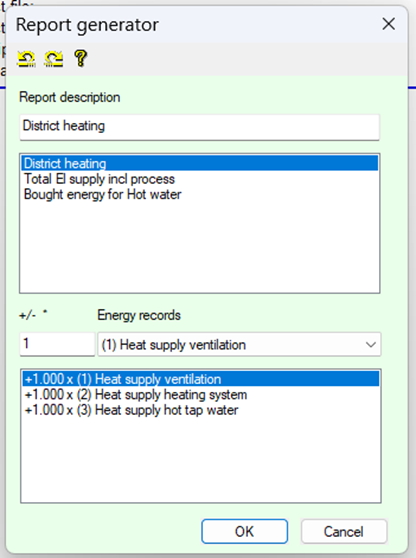

Report Generator |

|

The user can use the dialogue to customize reports based on all data in the energy calculation. Every report or summary is named and under that name all fields (or energy flows in the model) can be added or subtracted. In each report, a field can only appear once. In the result menu the user can select to show the appropriate reports. |

|

| |

|

| Top of page |

|

| |

|

Project data |

|

All data except title must be accepted before the calculation can start. The result is lost if the user changes the input data. |

|

| |

|

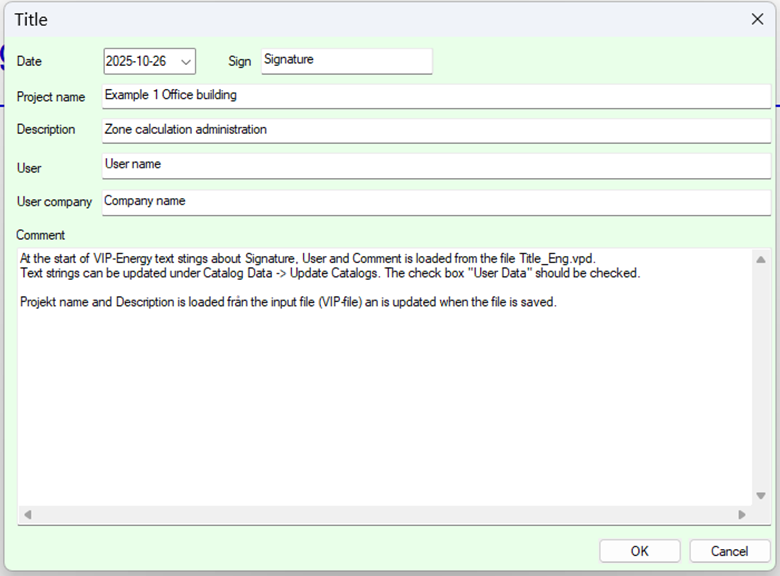

Title |

|

|

|

| This dialog window contains description and comments about the project. Data has no impact on the calculation. Project name will be the title of the result print. Description is used for a shorter description of the current calculation. Comment is a text area for elective information for the user about current project. Date is filled in from the computer’s internal watch at a new calculation. Date, sign, project name, description an comment is stored in the project. User, User company and Sign is filled in by the user and stored in catalog file. The information is stored under “Update catalog data” and a check for User Data |

|

| |

|

|

|

Climate information |

|

|

|

| Restrictions:

| Value: |

Value: |

Max: |

Unit |

| Horizon angle |

<0 |

<=90 |

degrees |

| Air pressure |

>0 |

|

hPa |

| Wind speed |

>0 |

|

% |

|

|

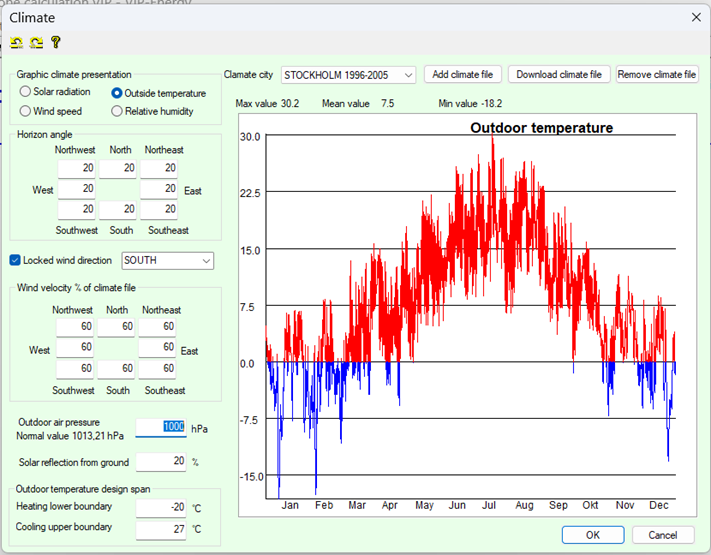

City |

|

The user chooses City by election from a combined text and list box with cities where climate data is available. The program can be completed with further climate data which will be delivered by SMHI or Meteonorm. When the city has been chosen climate data will be shown in a graphic picture which can show either outside temperature, solar radiation, wind velocity or relative humidity. |

|

| |

|

Air pressure outside |

|

The user can adjust for level over sea with air pressure. Air pressure has an impact on air density as well as on heat transport. The pressure is sinking with 1 hPa for every 8 meter up to 500 meter over sea level. Normal air pressure at see level is 1013,21 hPa. |

|

| |

|

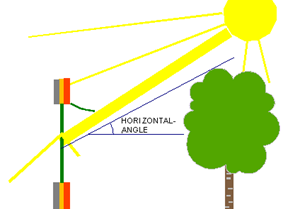

Horizontal angle |

|

Shading is given by feeding the horizontal angle for eight sectors. Shading is used for calculation solar radiation.  |

|

| |

|

Locked wind direction |

|

The software can get the wind direction from a climate file if that contains necessary data. The locked direction will be used when using an older climate file that does not contain wind direction or when the local main wind direction is different than at climate station. The user can always lock the wind direction by using the check box. |

|

| |

|

Wind velocity % of climate file |

|

The value tells how big share of the wind load of the climate file that hits the building. |

|

| |

|

Solar reflection from ground surface |

|

The value represents the share of solar radiation reflected from the ground towards the building. A dark surface has a low value and a water surface has a high value. Normal values are 20-50 %. |

|

| |

|

Designing outdoor temperature |

|

Input for designing outdoor temperatures for heating and cooling. If the outdoor temperature exceeds the maximum temperature for cooling the room temperature limit is following up. The same happens for low temperatures and heating. |

|

| |

|

|

|

Building |

|

|

|

| |

|

Generic |

|

The building dialog window is used to combine building parts to a building. Amount of building parts an there orientation is needed. If the building part contains a heat layer the heat layer load is defined as a share of total heat demand to room air. The input of building parts can be written directly in the edit box or copied from one of the catalog windows with the commanding buttons under the list box. By clicking one of these button a dialog box will show up with the content of the catalog. With a click on one of the rows and then one click on OK, the building part will be copied in the right box in the input row. The framed input windows for heat transfer are only available on validation mode. |

|

|

|

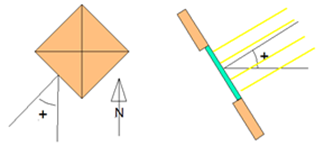

Orientation |

|

The orientation INNER1 and INNER2 is used to describe the interior building parts where both sides have contact with indoor temperature. Construction parts has an inner and outer side. It's the last specified material layer, which is defined as the Interior. If INNER1 is selected heat exchange is calculated only between current zone and the inner surface. The outer surface is in this case assumed as border towards another zone with the same temperature as current. If INNER2 is selected heat exchange is calculated between current zone and both surfaces. The orientation is chosen for the interior walls and intermediate floor within current zone. For INNER1 and INNER2 orientation the Lowest level and Highest level will be inactive and the values will not be used in the calculation. Inner walls can be used as separating walls between the rooms that are included in the calculation and towards adjacent rooms with same temperatures. All building parts, inner and envelope, are interacting by heat radiation. So inner parts are important both as heat capacity and heat exchange between room air and envelope via radiation from inner to envelope surfaces. If TEMP is used as orientation, the building part will be calculated as a border to another room with a constant temperature like cooling room. In building code contexts TEMP building parts is sorted as envelope. The orientation TEMP-I has the same function as TEMP with the exception that TEMP-I is not involved in the envelope area. When using TEMP_O stand for outdoor temperature independent of solar radiation and the area of the building part is excluded from the envelope area in building code context. Compass point orientation are facing outside surface temperature which are depending on solar radiation and outdoor temperature. Orientation contains a number of alternatives of calculation of building parts towards ground. The choice of underground properties influences the calculation of transmission through ground. |

|

|

|

SOG: Slab on grade BW: Basement wall BF: Basement floor ROOf is treated as horizontal surface facing upward. For tilted roof use compass point and tilting function. |

|

| |

|

Rotation and tilting |

|

Each building part can be rotated and tilted separately. Zero value for tilting means that surface is vertical. Tilting value is only valid for compass point orientations. |

|

| |

|

Heat layers and share of heating demand |

|

For using a heat layer in the building construction the percentage part of the needed power that the heat layer should cover must be stated. The design of the building part is directly reflected in the energy consumption. If the heat layer is close to heat accumulating material the user will get a control inertia that can counteract energy savings. On the other hand, less insulation outside the heat layer can increase the need of heat transmission of the building. In this dialog the U-factor including delta U is shown. |

|

| |

|

| Ventilation volume |

|

Used for calculations of airflows in ventilation systems. The ventilation volume is multiplied with the number of changes per hour that will be fetched from Time controlled ventilation and Temperature controlled ventilation. The volume i even used for calculation of relative humidity that has an effekt on exhaust air heat pumps and latent part och energy for comfort cooling. |

|

| |

|

Floor area |

|

The area is multiplied with the quantity of energy per square meter that will be fetched from Catalog data- Operation cases and ventilation given as l/s, m² or m³/ h,m². |

|

| |

|

Number of apartments |

|

The number of apartments can be used in operation case catalogue to describe process energy and hot tap water. |

|

| |

|

The angle towards south |

|

The angle towards south is the angle between the surfaces having been given the direction SOUTH and the real angle towards south. If the building is turned clockwise the angle will be positive. |

|

| |

|

Levels |

|

The levels are the altitude localization of building parts and is needed for simulation of infiltration depending on stack effect. It is the height of cohesive air volumes that decides how levels are chosen. Normal values for 1 story apartments are 0-2,4 m. For an internal open office building the values can cover the whole building height. |

|

| |

|

Data import from VIP-Area |

|

The VIP-Area software is installed along with VIP-Energy. VIP-Area is used to organize measuring and calculation of amounts like areas and lengths. Data is stored in mngd-files that can be imported to VIP-Energy. Information about VIP-Area is in a separate manual. |

|

| |

|

|

|

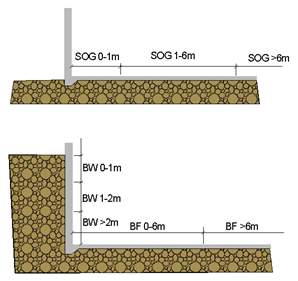

Time schedule for operation |

|

|

|

| |

|

Generic |

|

The dialog is used for organizing hours for predefined operation cases. All hours of the year must be covered and they cannot overlap. The colored fields is a help function to find out how much time is missing or overlapping. The bottom left field of the dialog has 53x24 squares and is valid for the with the tabs chosen day of the week. Each square represents one hour of the chosen day. Light or dark green squares indicate that the input is OK, yellow squares indicate hours that have no input, and red squares indicate double input. The field for each day of the week gives an overview of the input. |

|

| |

|

Time schedules |

|

Operation hours are stored in time schedules that can be stored as catalog data. A time schedule which is created for operation cases is even available under Economy and Time controlled ventilation. |

|

| |

|

Date function |

|

The function is used to translate date to week number. Operation times and operation cases are stated in seven dialog tabs, one for each day of the week. |

|

| |

|

Remaining time |

|

It is also possible to state an operation case for remaining time, i.e. hours that is not stated in the table. The function reduces the amount of work for schedules with a base operation case which is completed by different other cases. |

|

| |

|

Operation case |

|

Names for predefined operation cases can be retrieved from the Operation Case Catalog by pressing “Control Case Catalog”. The name will be copied into the right input box with a click on a row in the catalog list and then press OK |

|

| |

|

Operation hours |

|

Start time and end time must be within the same day and is valid from start week to end week. The start time is therefore always to be less than the end time. All 53 weeks has to be covered. |

|

| |

|

Operation year |

|

The software retrieves information on the connection between weekday and date for chosen operation year from the calendar function. If January 1st happens to be e.g. a Wednesday then the calculation will start with Wednesday. |

|

| |

|

Copy |

|

It is possible to copy data between the days of the week. If the user has chosen to e.g. copy Tuesdays from Mondays then even Tuesdays will be updated when Mondays are edited. |

|

| |

|

4.7.4.9. Limitations

| Value |

Min |

Max |

| Start week |

>=1 |

<End week |

| End week |

>Start week |

<=53 |

| Start time |

>=0 |

<=End time |

| End time |

>Start time |

<=24 |

|

|

|

|

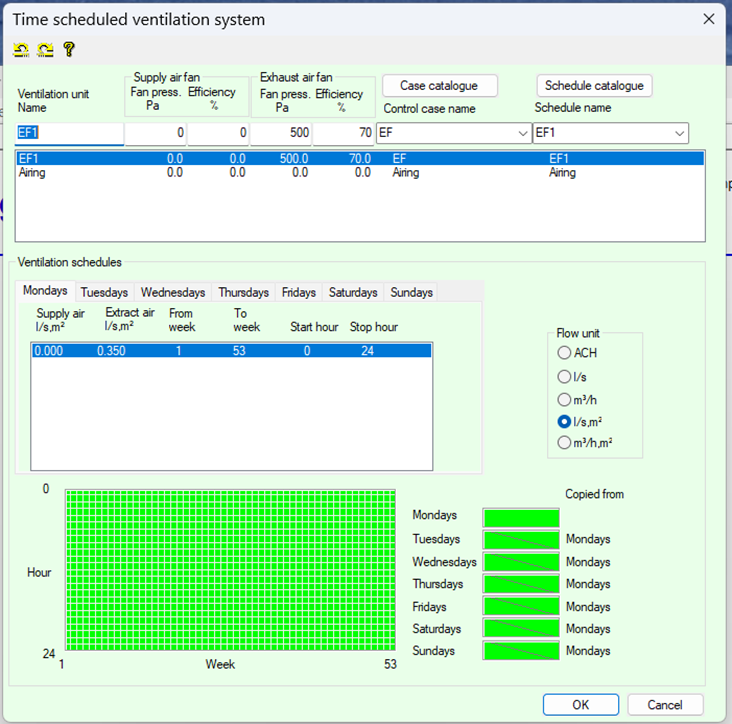

Time scheduled ventilation systems |

|

|

|

| |

|

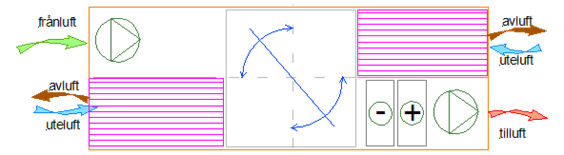

Generic |

|

In the ventilation system dialog possible an arbitrary number of ventilation units can be added. Each unit can hold a ventilation flow schedule. Each day of the week can have a schedule of its own. Data is can be copied among the days of the week. Each unit has its own set of properties which are stated on the same line as the unit name. A unit that in real life is run with various properties during the day is stated as several units, one for each operation case. Control functions are being specified as separate control cases that are stored in a control case catalog. |

|

| |

|

Fan pressure |

|

Fan pressure is used in combination with efficiency for calculating consumed electric energy for the fan. Normal values for fan pressure extract air No heat recovery: 200 Pa Heat recovery: 500 Pa Normal values for fan pressure supply air: No heat recovery: 300 Pa Heat recovery: 600 Pa |

|

| |

|

Fan efficiency |

|

The efficiency states what work the fan has performed in relation to consumed electric energy. Normal value: 50-60% Fan efficiency is not to be mistaken for the efficiency for the heat recovery system. Electric power = fan pressure * flow / efficiency |

|

| |

|

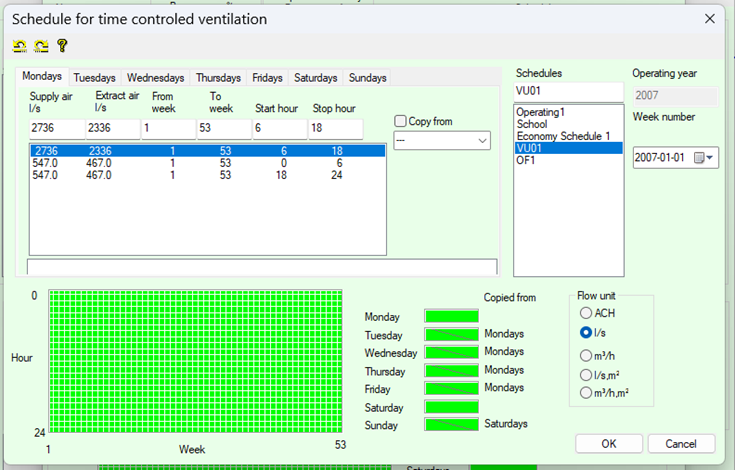

Operating hours |

|

|

|

For each ventilation unit, operating hours and flow are entered. Each unit has its own set of operating hours. Operating hours is stored in schedules that can be saved as catalog data. Schedules created for ventilation hours are also available for operating and energy tariffs. |

|

Operation year |

|

The software considers relations between weekday and date for chosen operation year. |

|

Time schedule ventilation General The input window is used to time control fan flows. Only hours with flows need to be specified. Remaining time In addition to specific weeks and hours, there is also the option to provide flows for remaining time, and this applies to weeks and hours that are not specified in the table. If a ventilation flow is used continuously, you can set it as remaining time. |

|

|

|

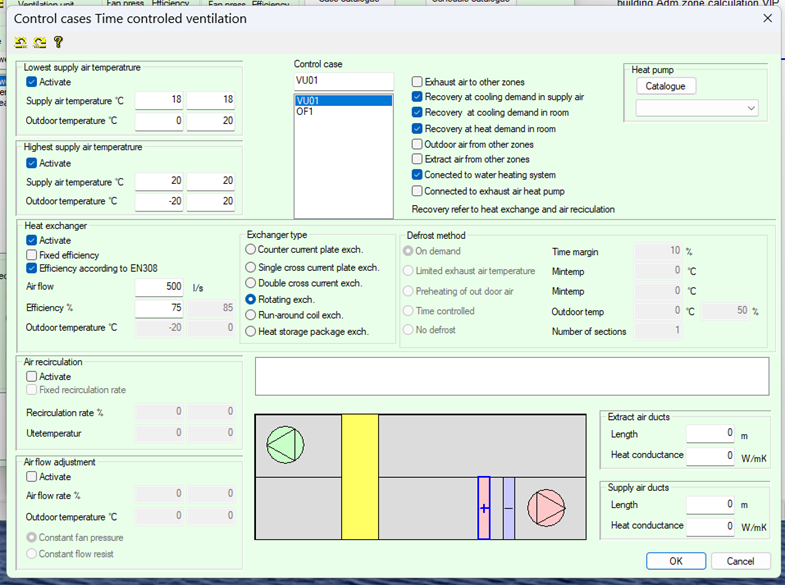

Control case catalog |

|

|

|

|

|

| |

|

Generic |

|

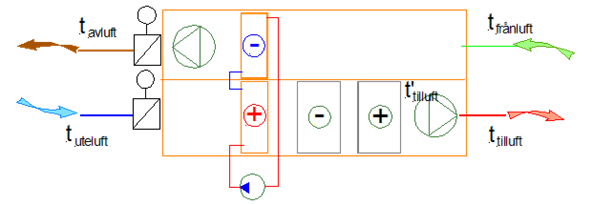

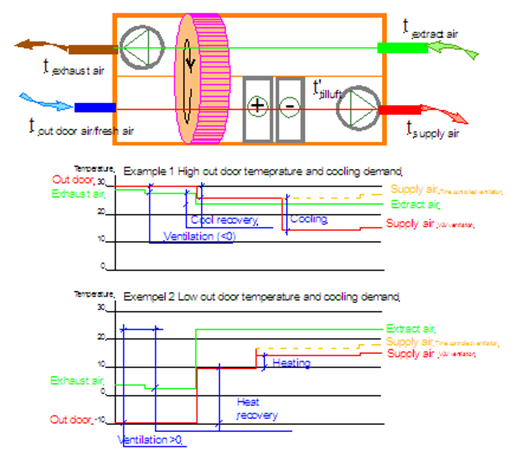

Under the Time controlled ventilation dialog there is a dialog with control cases. Maximum and minimum for supply air temperature, heat recovery, air recirculation and flow regulation are controlled with consideration to two various outdoors temperatures. In the validation function mode there are some extra function that is not used in normal projects. The validation function mode can be activated under the View menu. |

|

| |

|

Lowest supply air temperature |

|

Lowest allowed temperature for supply air with consideration taken to condensation, comfort etc. The supply air temperature is raised to the stated value irrespective of room temperature. |

|

| |

|

Highest allowed supply air temperature |

|

Highest allowed temperature for supply air. Supply air temperature is lowered to the stated value. |

|

| |

|

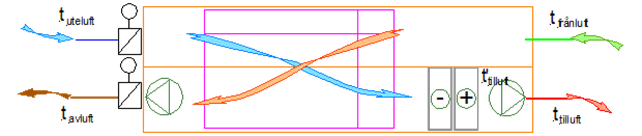

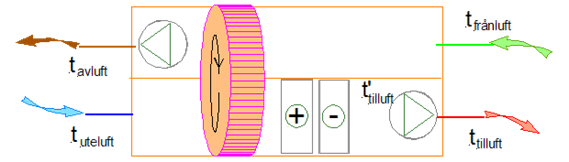

Energy efficiency for exchanger |

|

The energy efficiency of the heat exchanger states the extent of the recovered amount of energy from the exhaust air. This is normally slightly less than the temperature efficiency when it comes to a raise of the supply air temperature in relation to the indoor-outdoor temperature difference. Standard values:

Rotating exchanger: 70-90%

Cross current plate exchanger: 50-60%

Counter current plate exchanger 70-90 %

Run-around Coil Heat Exchanger 50% |

|

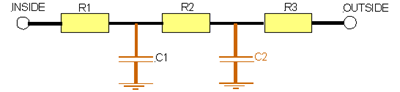

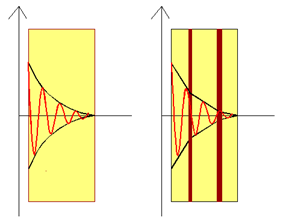

Efficiency according to EN308 Normally you should use values measured according to standard EN 308. Indication of the efficiency at which flow the measured defines the exchanger properties. Efficiency is flow dependent and a recount is done internally by the program. Type of heat exchanger The program includes simulation models for the most common types of heat exchangers. Initially, the program creates a computational model of the exchanger with the test data according to a 308. Test data must contain efficiency and associated test flow that should be equal for supply air and exhaust air. Testing according to a 308 takes place without condensation or icing. The program calculates the hourly heat, condensation, icing and defrosting and moisture recycling in the light of current conditions. Defrosting method In the plate heat exchangers and Run-around coil changer frost is formed of the moisture which is added into the room air, if the outdoor temperature is a few degrees below zero. The program includes computational models of the most common methods to defrost the exchanger. Demand-controlled defrosting means that there is a function that records if it formed the frost and that reduces recovery by bypassing the cold outdoor air in plate exchangers or close the liquid flow in the Run-around coil exchanger as long as is necessary to melt the ice. The calculation simulates the optimal conditions. Therefore, there is the option to add a time margin. If nothing else is known the margin is set to 50%. Number of sections If the exchanger is defrosted through by-pass of the whole cold air flow the whole power of heating of outdoor air is transfered to heat coil. If the heat exchanger is divided in two halves power requirements for heating coil. Theoretically number of sections is limited depending on the time necessary for defrosting. If 6 min defrost requires per hour, it is not possible to use more than 10 sections. The program maximizes automatically number used sections, taking into account the estimated defrosting time. Information about defrosting method obtained from ventilation unit provider. More detailed information on heat exchangers are provided in section 6. |

|

Efficiency for recirculation |

|

The efficiency intends recirculation flow compared to extract air flow. Recirculation flow is maximized to supply air flow independent of efficiency input. |

|

| |

|

Regulation of airflow according to outdoor temperature |

|

The airflow can be regulated according to outdoor temperature. The flow is stated in % of the in the time schedule stated flow at two different outdoor temperatures. If the outdoor temperature is below or above the two given outdoor temperatures then value of the nearest outdoor temperature will be valid |

|

The regulation of air flow can be achieved by the fan speed changes with or without the restriction of air flow with a damper in the duct system. If the raegulation takes place without damper is the flow resistance is constant. Fan pressure changes proportionally to the square of the flow. Alternatively fans are controlled to constant fan pressure and flow by throttling the flow in the duct system. |

|

Cool recovery |

|

The heat exchanger will be used for cooling supply air when there is a need for cooling and when the extract air temperature is below the outdoor temperature if the box is checked. |

|

| |

|

Fresh air supply from other zones |

|

This option is for multi zone calculations. Fresh air temperature and humidity will be taken to the ventilation unit from a mixture of air from different zones and outdoor air. The mixture is specified in the in data dialog for zone calculations. If no share from other zones is stated outdoor air temperature will be used. |

|

Exhaust air supply from other zonesThis option is for multi zone calculations. Exhaust air temperature and humidity will be taken to the ventilation unit from a mixture of air from different zones. The mixture is specified in the in data dialog for zone calculations. If no share from other zones is stated 100 % share is from the current zone. |

|

Fixed efficiency for recirculation In normal operation recirculation is active in case of heat or cooling demand. If the function for efficiency locking is active the regain is continuously active. |

|

| Fixed efficiency for heat exchange n normal operation heat exchange is active in case of heat or cooling demand. If the function for efficiency locking is active the regain is continuously active. |

|

Ventilation ducts Heat release from cold-placed ventilation ducts. Heat release is calculated using air temperature in ducts, outdoor temperature and the product of length and heat release. In cases where insulation varies between different channel sections, a weighted average is used. Heat pump Heat pumps of the type "Exhaust air/Supply air" can be integrated into ventilation units. Only that heat pump type is shown in the list. |

|

|

|

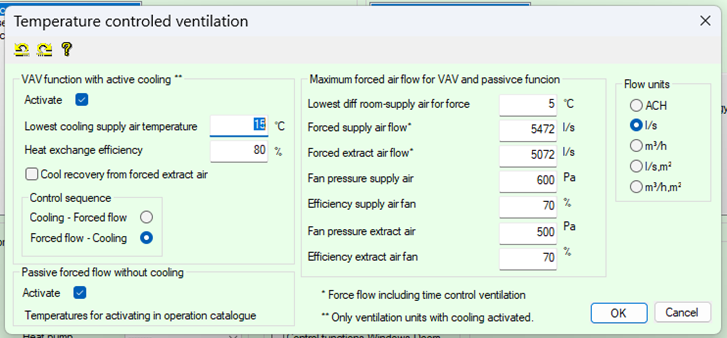

Temperature controlled ventilation |

|

|

|

| |

|

Temperature controlled ventilation with passive forced flow |

|

To handle cooling with air there are possibilities to force the air flow if the room temperature exceeds a certain temperature. No heat or cool supply to the forced air flow. |

|

| |

|

Forcing air flow over room temperature |

|

The temperature states the room temperature where forcing of the air flow is done. The value is given in the operation case catalog. |

|

| |

|

Lowest temperature difference room-supply air |

|

The lowest allowed temperature difference between supply air and room air to activate the forced flow. |

|

| |

|

Total forcing flow supply air |

|

Total forcing flow of supply air for the whole building including time controlled ventilation. |

|

| |

|

Total forcing flow extract air |

|

This is total forcing flow of exhaust air for the whole building including time controlled ventilation. |

|

| |

|

Fan pressure supply air |

|

Fan pressure for the forcing flow in addition to time controlled ventilation. |

|

| |

|

Efficiency supply air fan |

|

The efficiency states the accomplished fan work in relation to consumed electric energy. |

|

| |

|

Fan pressure extract air |

|

Average fan pressure for the forcing flow for the whole building. |

|

| |

|

Efficiency extract air fan |

|

The efficiency states the accomplished fan work in relation to consumed electric energy. |

|

| |

|

Temperature controlled ventilation with cooling (VAV system) |

|